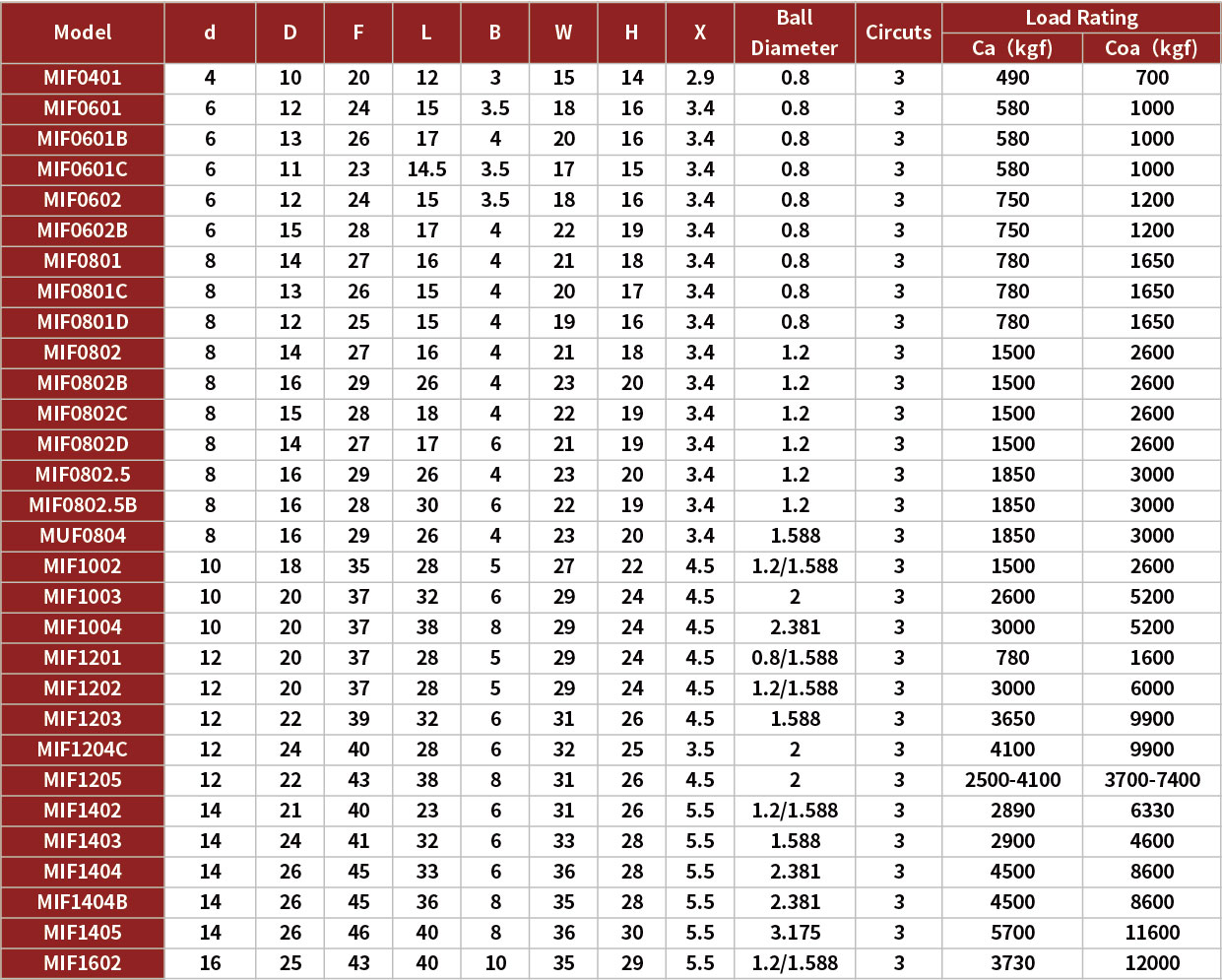

Model No.: MIF0602

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

A Ball Screw is a mechanical transmission component that uses rolling steel balls between a threaded shaft and a ball nut to transmit motion. It consists of a threaded shaft, a ball nut, and a series of steel balls that roll between the shaft and the raceways. The rolling balls facilitate the transmission and conversion of power, enabling both linear and rotary motion.

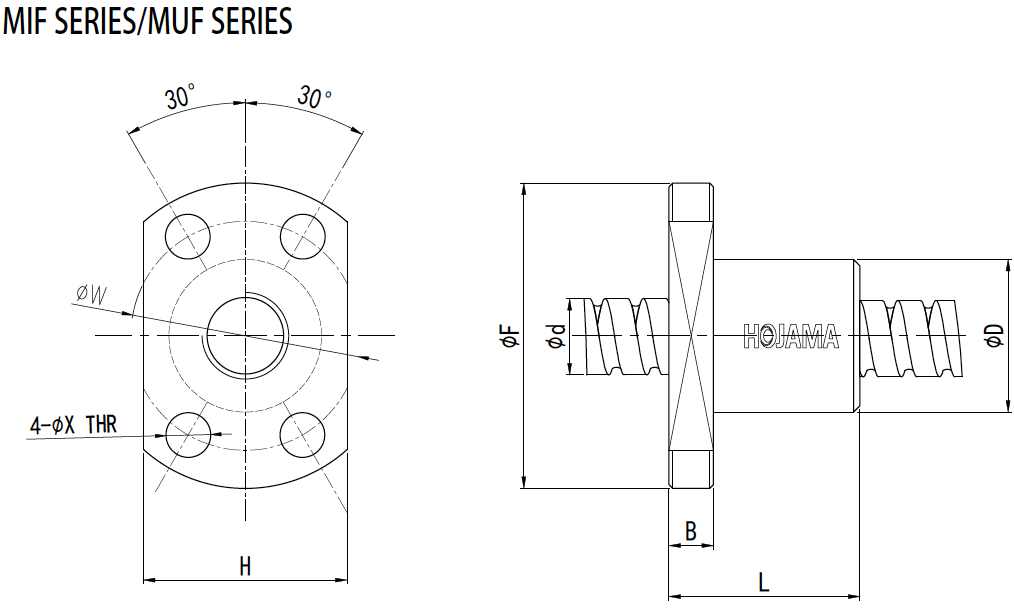

1) Nut Type: The MIF0602 ball screw features a standard nut, durable and wear-resistant, commonly used in linear motion applications.

2) Circulation Method: The Miniature Ball Screw Assembly employs a round floating deflector return system, ensuring smooth and efficient circulation during transmission.

3) Nut Shape: The screw with the ball has a round nut with a flange design. The flange provides additional support and mounting options, ensuring stability and proper alignment within the linear motion system.

A motor mount is a high-concentricity product that connects ball screws and motors. It integrates paired angular contact bearings (with precision grade C5 or higher) to achieve higher accuracy, ensuring zero axial backlash of the ball screw set during motor forward and reverse rotations, making it particularly suitable for high-speed equipment.

1. Simple installation: One end of the motor mount is matched with the motor, while the other end, which contains paired angular contact bearings, can be installed following the ball screw installation procedures, resulting in simple operation.

2. Assembly accuracy: The ball screw and motor are integrated through the motor mount, reducing the concentricity error between the motor shaft and the ball screw shaft to within ±0.01mm, and controlling the perpendicularity of the end face to 0.01mm.

3. Machining accuracy: The overall shape of the motor mount is formed in one piece through mold opening, and then the mounting contact surfaces are finished with precision machining to ensure accuracy.

1. For specific product pricing, please consult HOJAMA and provide the CAD and 3D drawings of Miniature Ball Screws, as well as the product quantities.

2. We are pleased to provide samples so you can assess the quality and suitability of our products for your requirements.

Product Categories : Miniature Ball Screws > 6mm Diameter Ball Screw