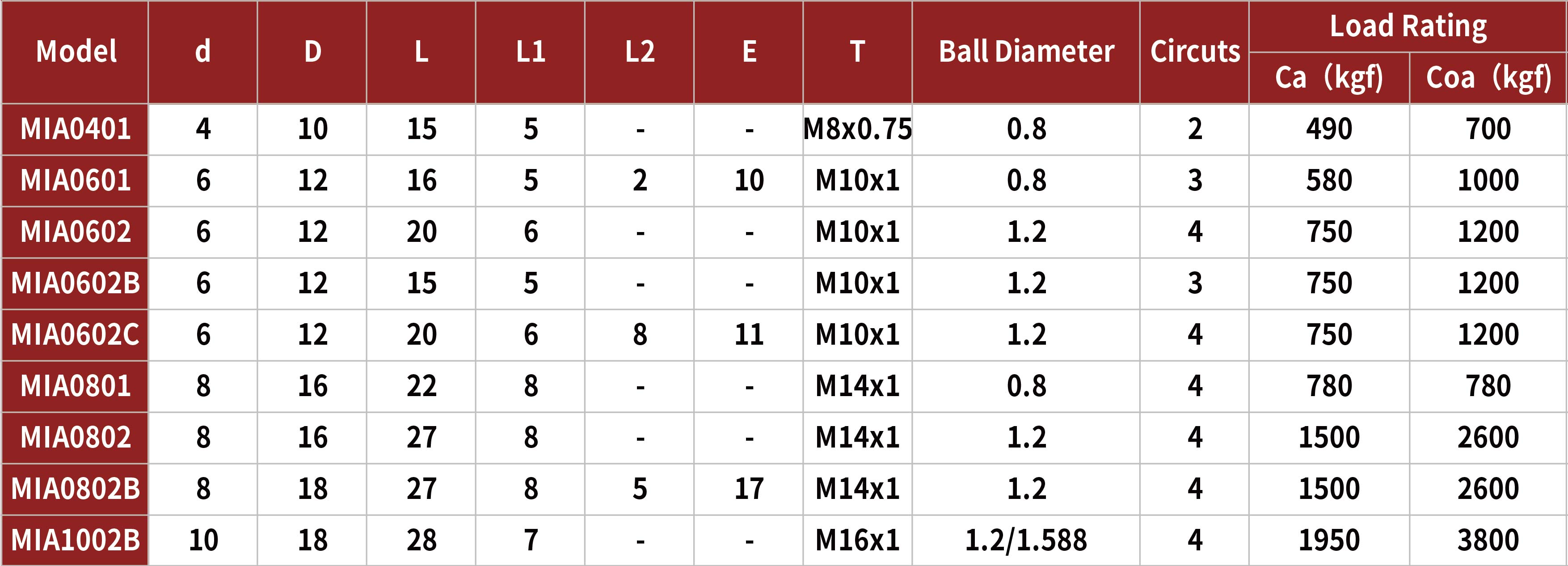

Model No.: MIA0602B

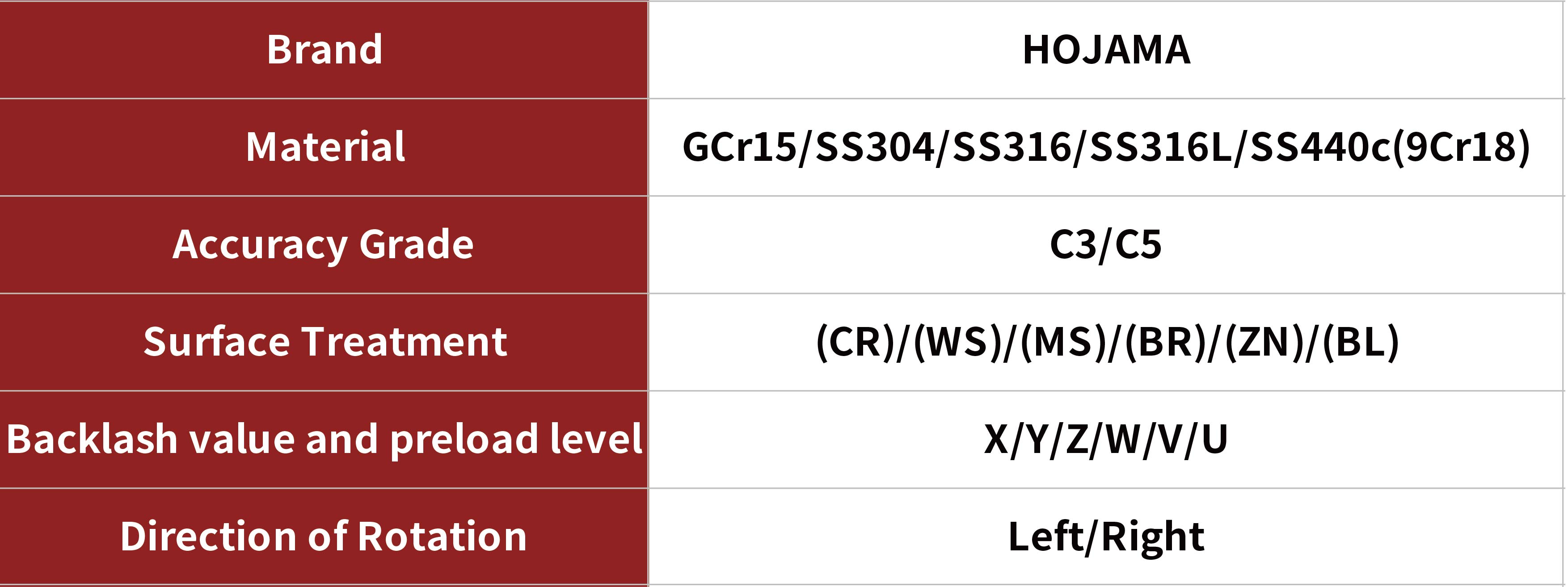

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

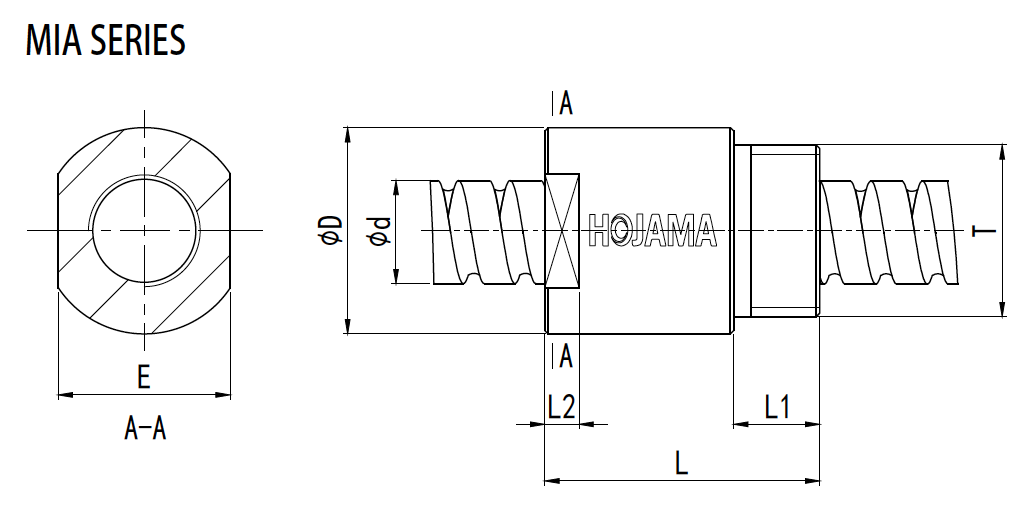

Type: Miniature Ball Screw

Lead/Pitch: 2mm

Nut Type: Standard Nut

Cycle Mode: Floating Deflector

Nut Shape: Round Nut with Triangular Thread

Ball screws are usually used together with guiding components (such as linear guides, linear bearings). The ball screw mechanism only provides the axial force required for the worktable to move in the linear direction through the ball nut, while the worktable (as a load) and all radial loads and torque loads it bears are carried by high-rigidity guiding components like linear guides.

During operation, the ball nut of a ball screw cannot bear radial loads or torque loads but only loads along the axial direction of the screw. It is important to ensure that the axial load acting on the ball screw pair passes through the axis of the screw. In design, radial loads and torque loads must not be directly applied to the nut; otherwise, the service life of the ball screw mechanism will be significantly shortened, or malfunctions will occur. This is because radial loads or torque loads will cause the screw to bend, leading to overload on some balls in the nut, which in turn results in unstable transmission, reduced precision, and a sharp decrease in service life.

Miniature Ball Screws, as a kind of precise transmission component, are widely used in various systems where space is limited but needs high precision.

1) High efficiency

2) High precision

3) Durable Design

4) High Rigidity

5) Low Noise

6) Compact

1) Medical Device

2) Automotive Industry

3) Aerospace

4) Robotics

5) Precision Manufacturing

1) The final price is based on product quantity and parameters specified in your drawings (CAD and 3D formats).

2) Should you still have uncertainties, requesting a sample might provide insight into the product's quality and performance.

3) Lead time: 15- 25 days. For more details, don't hesitate to get in touch with HOJAMA.

Product Categories : Miniature Ball Screws > 6mm Diameter Ball Screw