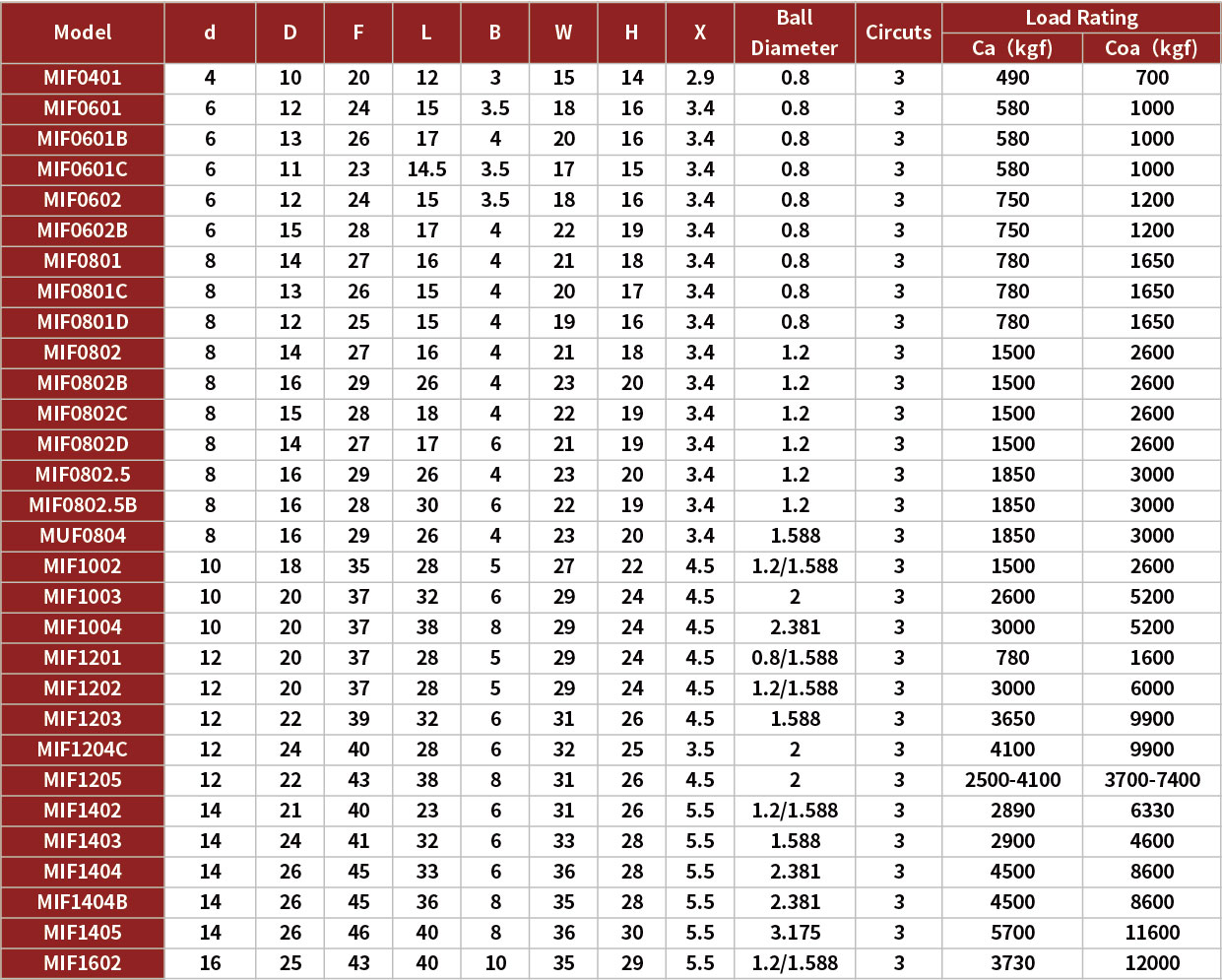

Model No.: MIF0601B

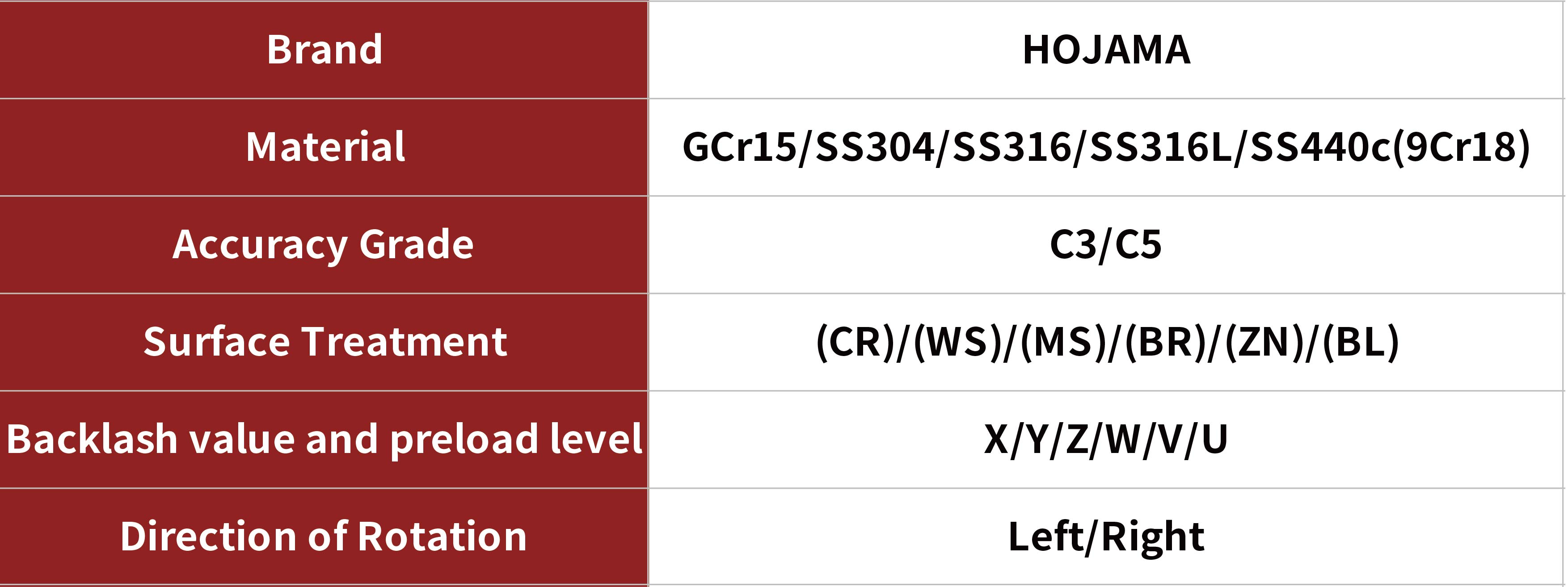

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

Due to the rolling motion of the steel balls, ball screws and nuts are more efficient than sliding screws, requires less driving torque and saves energy.

The precision screw with the ball is made with advanced machinery and strict control of temperature and humidity, ensuring high accuracy through rigorous quality management.

Compared to other high-Precision Ball Screws, mini ball screw assemblies are designed in a smaller size, making them ideal for compact or confined applications.

Despite their small size, micro ball screws are capable of handling significant loads due to their robust design and advanced engineering.

The screw-in ball provides smooth and consistent motion with minimal backlash, ensuring precise and reliable operation in various applications.

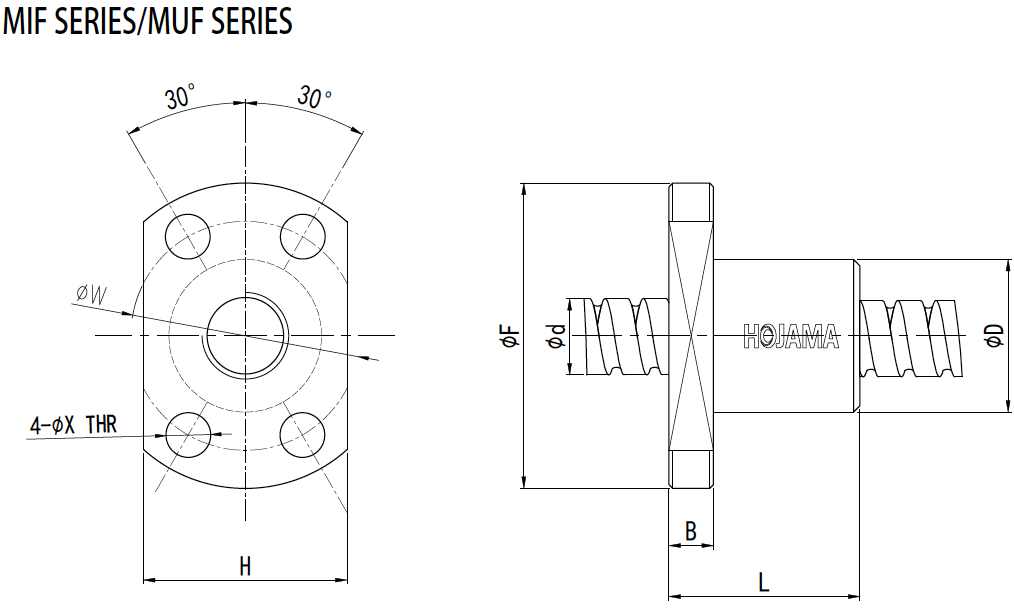

A ball screw bearing housing generally consists of an inner ring, an outer ring, rolling elements, and a cage. The inner ring is designed to fit with the shaft and rotate together with it; the outer ring functions to match the bearing housing and play a supporting role. The rolling elements are evenly distributed between the inner and outer rings using the cage, and their shape, size, and quantity directly affect the performance and service life of the rolling bearing. The cage ensures the even distribution of rolling elements, prevents them from falling off, guides their rotation, and provides a lubricating effect.

1. Secure the ball screw to the table surface of the positioning slide slightly.

2. Assemble the fixed end with the bearing at the tail end of the screw.

3. Verify the parallelism between the guide surface of the slide and the ball screw, then lock and fix the fixed end and the support end.

4. Push the slide to both ends of the stroke to ensure the smooth operation of the ball screw, and then lock and fix the screw to the slide.

1) The real price of the Miniature Ball Screws depends on the parameters of the CAD or 3D drawings you provide and the quantity of the required products.

2) Samples can be requested for evaluation and testing purposes.

3) The delivery time is usually 15 to 25 days. For a more precise estimate, please contact HOJAMA with your details.

Product Categories : Miniature Ball Screws > 6mm Diameter Ball Screw