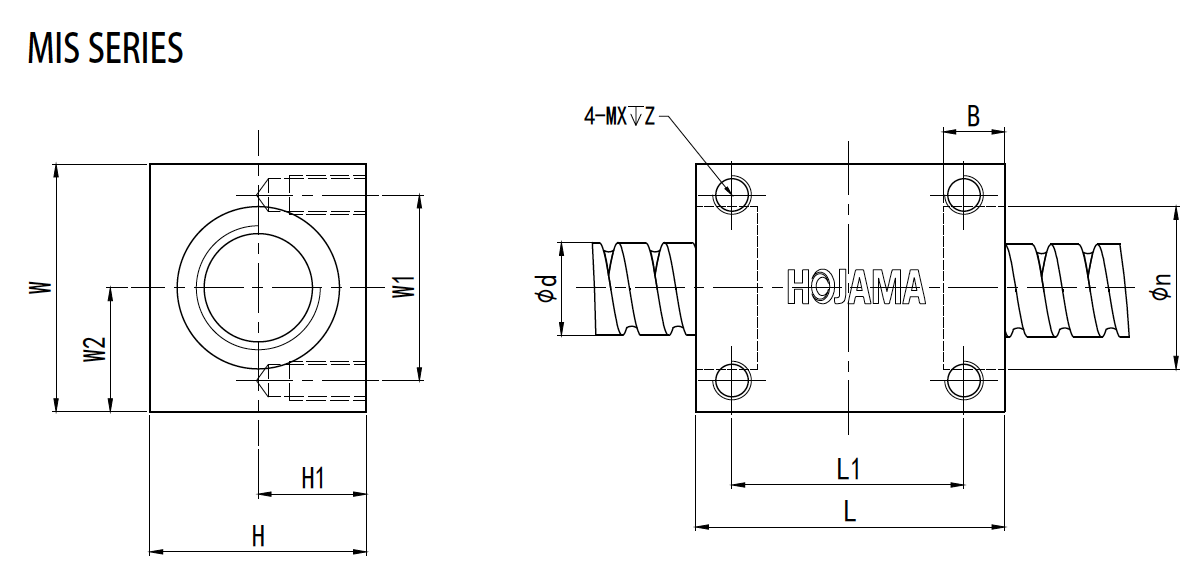

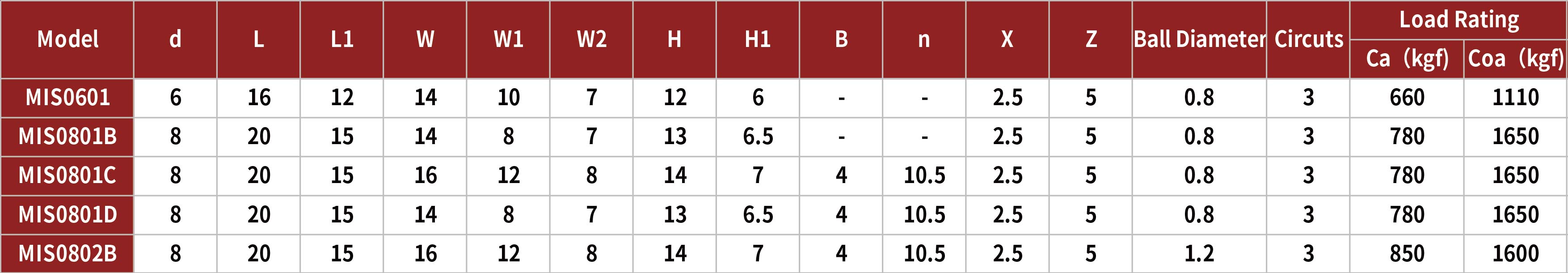

Model No.: MIS0801C

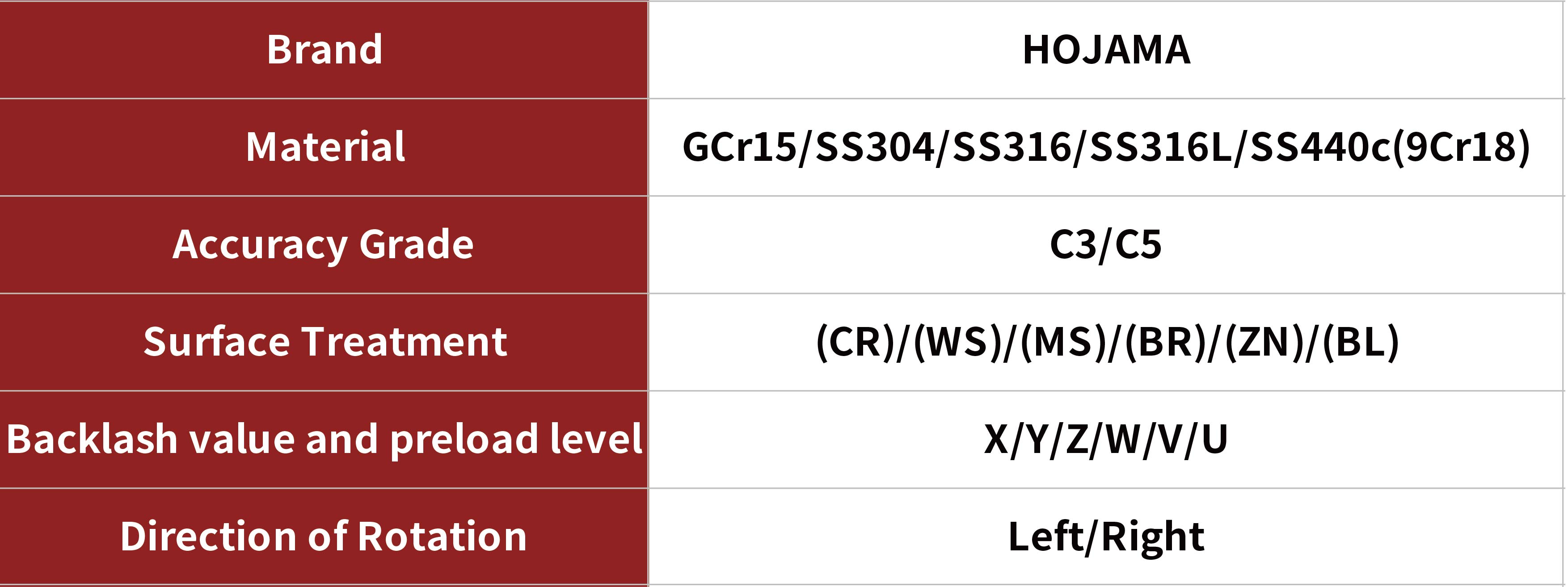

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

The internal recirculating Ball Screw comprises a screw shaft, nut, steel balls, and a return cover. The steel balls circulate in a single loop, with the return cover connecting two adjacent ball grooves and redirecting the balls to form a closed return path. The internal deflectors come in two shapes: round (such as MIS0801C) and waist-shaped.

This Miniature Ball Screw achieves transmission efficiencies up to 95%, making it one of the most efficient linear actuators available. The ball screw is available in C3 or C5 precision grade, which is critical for applications such as CNC machining and medical equipment. This mini-size ball screw offers versatile configurations, including single-start, double-start, and multi-start designs, allowing users to customize their linear motion systems to meet specific requirements.

(1) Insufficient lubrication of ball screw pairs can simultaneously lead to errors in various feed movements of CNC mechanical equipment. Therefore, ball screws' lubrication is a major part of daily maintenance.

The use of lubricants can enhance the wear resistance and transmission efficiency of ball screws. Hojama has two kind of ball screw lubricants: lubricating oils and greases.

Lubricating oils are generally total loss system oils, and greases can be lithium-based greases. Grease is usually applied to the thread raceways and the housing space where the nut is installed while lubricating oil is injected into the space of the nut through the oil hole on the housing. The grease on the ball screw kit should be replaced every six months. The old grease on the ball screw system should be cleaned off, and new grease should be applied. For ball screw pairs lubricated with oil, oil can be added once before the machine works each time.

(2) Regular Inspection of Ball Screw Support Bearings

Regularly check whether the connection between the ball screw support and the machine bed is loose, whether the connecting parts are damaged, as well as the working status and lubrication status of the ball screw support bearings.

1. Lead time: 15-25 days

2. HOJAMA product prices are determined based on the product quantity and specifications.

3. You are welcome to request samples for evaluation.

Product Categories : Miniature Ball Screws > 8mm Diameter Ball Screw