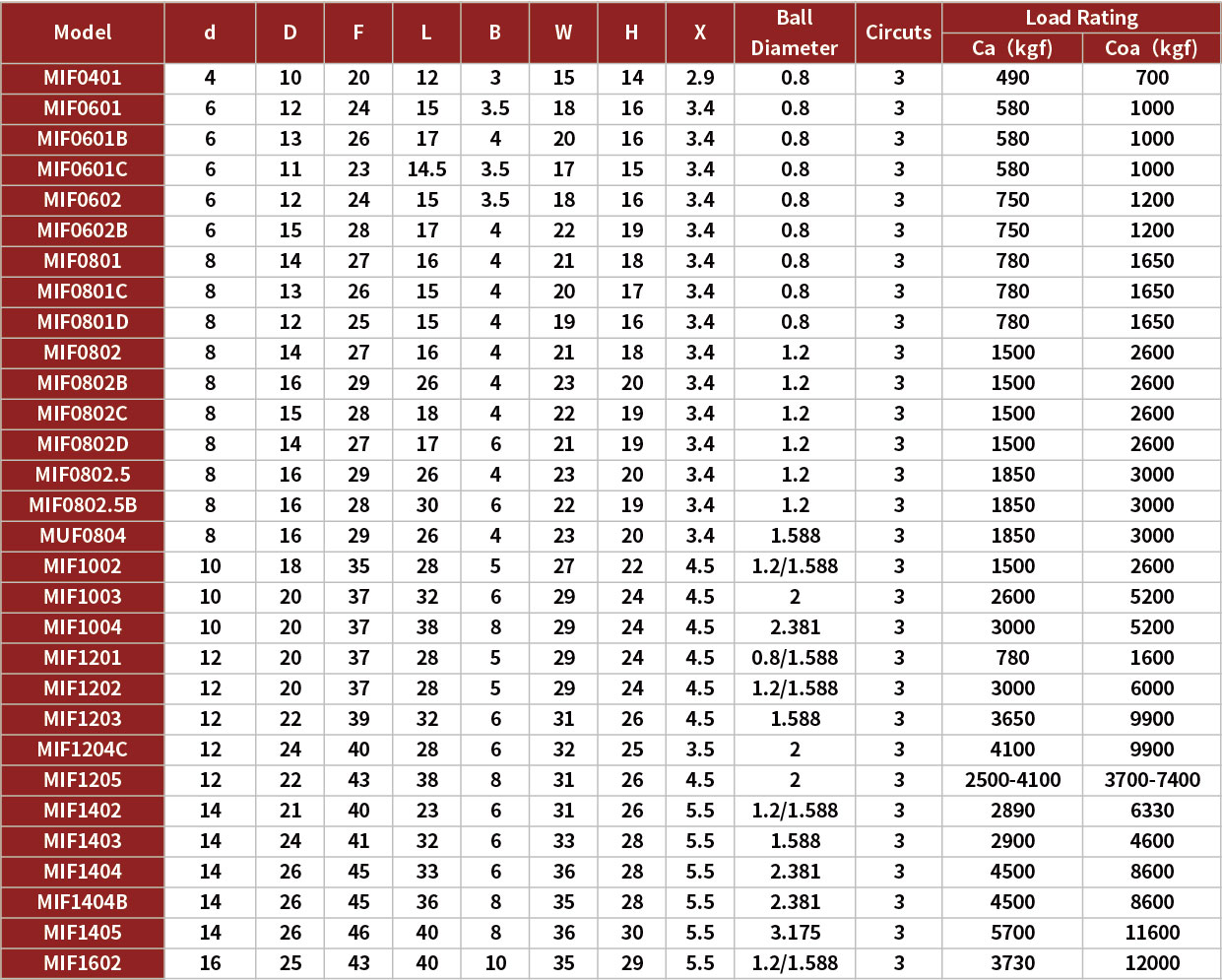

Model No.: MIF0801D

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

Lead/Pitch: 1mm

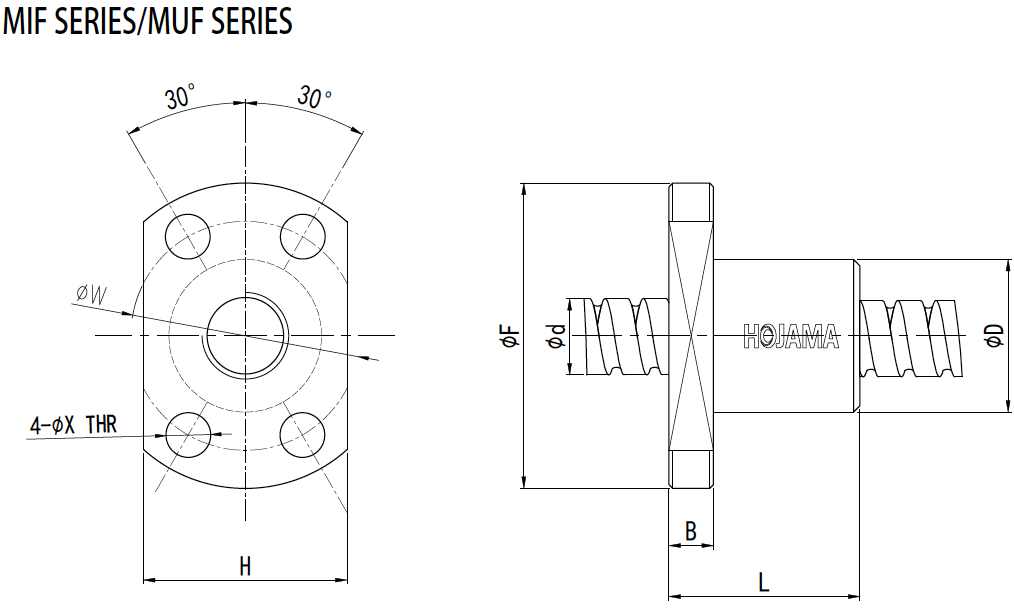

Nut type: Standard nut

Cycle Mode: Floating Deflector

Nut Shape: Flanged Round Nut(anti-backlash Ball Screw nut)

Shaft End: can be customized according to your needs

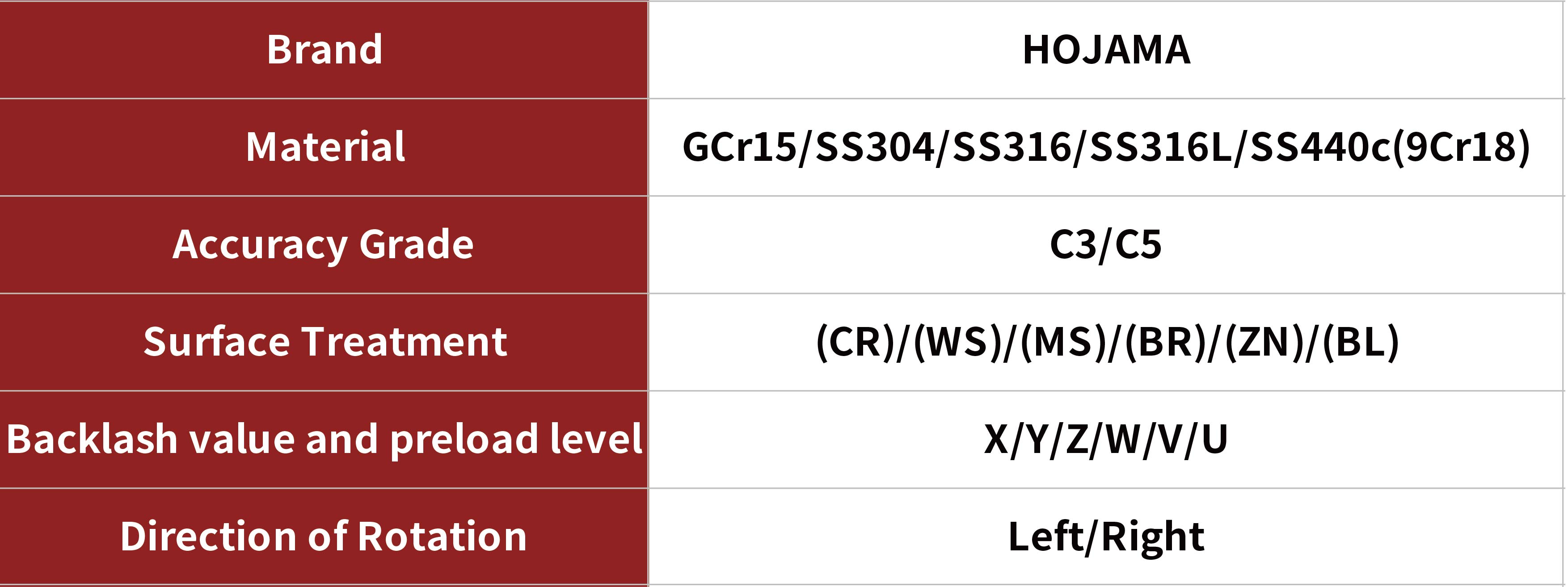

You can choose the accuracy grade based on your requirements, and they are available in C3 or C5.

Thanks to its low friction, the linear motion mini ball screw operates more quietly than others.

We will install the ball nut on the screw shaft in advance, which makes it easier to integrate the ball screw into various systems and ensure a smoother setup.

High-Precision Ball Screws: Used on occasions requiring extremely high positioning accuracy and repeat positioning accuracy, such as CNC machine tools, precision measurement equipment, etc.

General-Precision Ball Screws: Suitable for occasions where general transmission and positioning requirements are not high.

Self-Lubricating Ball Screws: Equipped with a removable oil removal device, no separate lubrication pipeline system and equipment are needed, reducing the costs of oil change and waste oil treatment.

Quiet Ball Screws: Through the specially designed ball spacer ring, the collision noise between balls is suppressed, making the movement quieter.

High-Speed Ball Screws: Featuring high acceleration, high feed rate, and high rigidity, they are suitable for fields such as high-speed cutting and longitudinal cutting.

Heavy-Load Ball Screws: Capable of withstanding large axial loads, suitable for heavy-load equipment such as air compressors and all-electric design machines.

Precision Ball Screws: Dozens of thread balls are in contact with the lead at the same time, with high precision, high rigidity, and high power density.

Ultra-Small Ball Screws: The thread diameter is less than 3mm, mainly used in small robots and micro-equipment.

Extra-Large Ball Screws: Developed for giant machines and equipment, the diameter can reach more than 120mm.

Rolled and Ground Screws: Rolled screws have low precision and are used in occasions with low precision requirements; ground screws have high precision and are suitable for high-precision occasions.

1. Ball screws are widely used in automotive power steering systems to convert the rotary motion of an electric motor into the linear motion of the steering rack.

2. The low friction resistance makes ballscrews ideal for applications in machine tools, robotics, and precision assembly equipment.

3. High-precision ball screw assemblies are essential in stepper motors for semiconductor manufacturing and similar applications.

4. Ball screws are utilized in 3D printers to achieve precise movement of the print head, ensuring high-quality and detailed output.

5. The screws with the ball are also used in solar tracking systems to adjust the angle of solar panels for maximum light exposure.

1. About price: according to the product specification and quantity.

2. About the sample: HOJAMA provides the sample for access.

3. About lead time: 15-25 days

Product Categories : Miniature Ball Screws > 8mm Diameter Ball Screw