Model No.: MIF0801

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

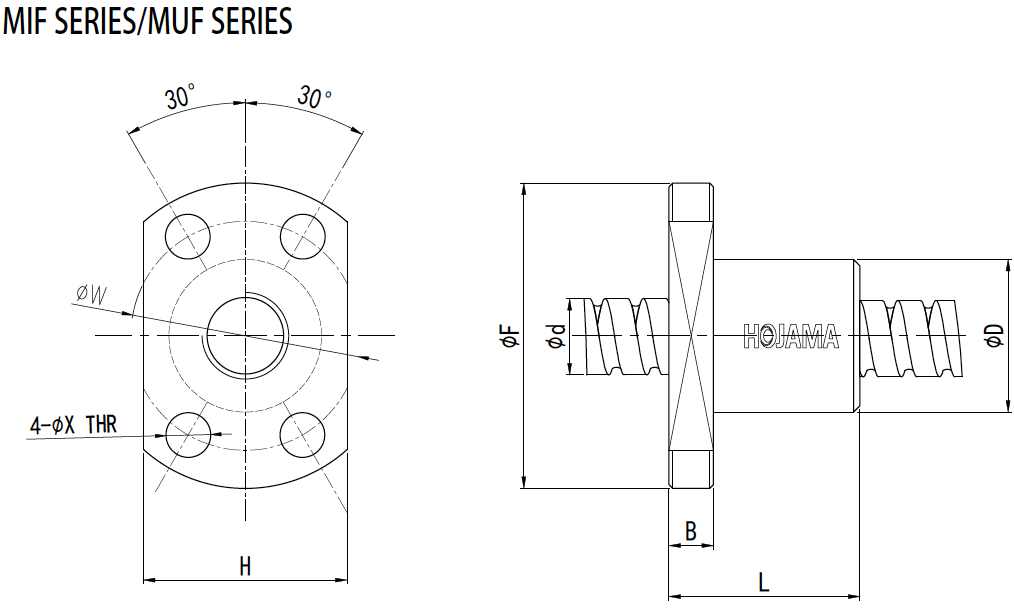

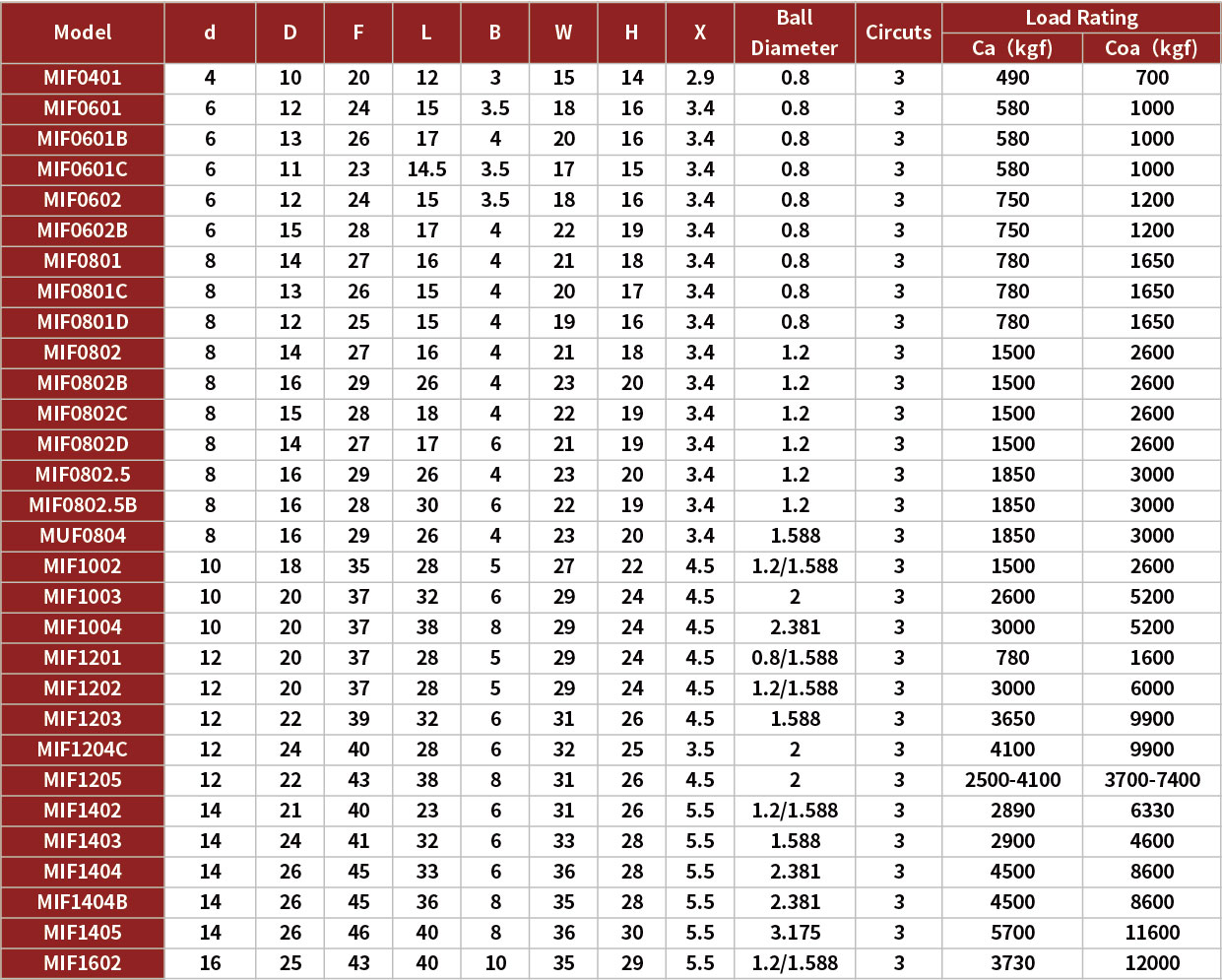

The MIF0801 is a 8mm diameter Miniature Ball Screw, designed for precision and efficiency. It features a 1mm lead and a flanged round nut for secure mounting and alignment. The ball screw includes a standard nut and an internal deflector for smooth operation and minimize friction. With a customizable shaft end, it offers versatility for various applications. Achieving efficiencies of 96% or higher, this efficient 8mm Diameter Ball Screw is ideal for high-accuracy and repeatability needs.

1. Ensuring high-precision linear motion: Through the rolling of balls between the threads and the nut, traditional sliding friction is avoided, which reduces friction, heat generation, and wear, and realizes high-precision positioning. It is a core component of high-end equipment such as CNC machine tools, laser cutting machines, and 3D printing equipment, providing a foundation for high-precision processing.

2. Improving transmission efficiency: Compared with sliding screws, rolling friction is smaller, resulting in higher transmission efficiency and less energy loss. It can reduce the burden on the drive motor, lower energy consumption, improve the overall efficiency of the equipment, and contribute to energy conservation and emission reduction, meeting the requirements of energy efficiency and service life for equipment that needs to work continuously for a long time.

3. Guaranteeing motion stability: With precise manufacturing processes, it ensures the stability and consistency of the motion trajectory, greatly improving the machining accuracy and repeat positioning accuracy of machinery. It is the key to the precise control of subtle motion changes in high-end equipment such as CNC machining centers and semiconductor manufacturing equipment, providing a "guarantee" for the production of high-precision products.

4. Reducing equipment noise: By adopting the rolling friction mechanism, it can significantly reduce the noise during operation, improve the working environment, and enhance the comfort of using the equipment. It meets the demand for a low-noise working environment in modern manufacturing equipment, which is beneficial to improving production efficiency and the health and well-being of employees.

5. Enhancing equipment reliability and durability: The self-lubricating property in its structural design reduces friction loss, thus ensuring a long service life and excellent durability. This enables high-end equipment to maintain stable working performance for a longer period, greatly reducing maintenance needs and costs. Especially in some core equipment, the reliability of the ball screw is directly related to the continuous operation ability and stability of the entire production line, and is a key factor to ensure efficient and stable production.

1. HOJAMA product pricing of Miniature Ball Screws is determined by the quantity and specifications of the product. Please provide CAD or 3D drawings for an accurate quote.

2. Lead time: 15-25 days

3. The sample is provided

Product Categories : Miniature Ball Screws > 8mm Diameter Ball Screw