Model No.: MIF0802B

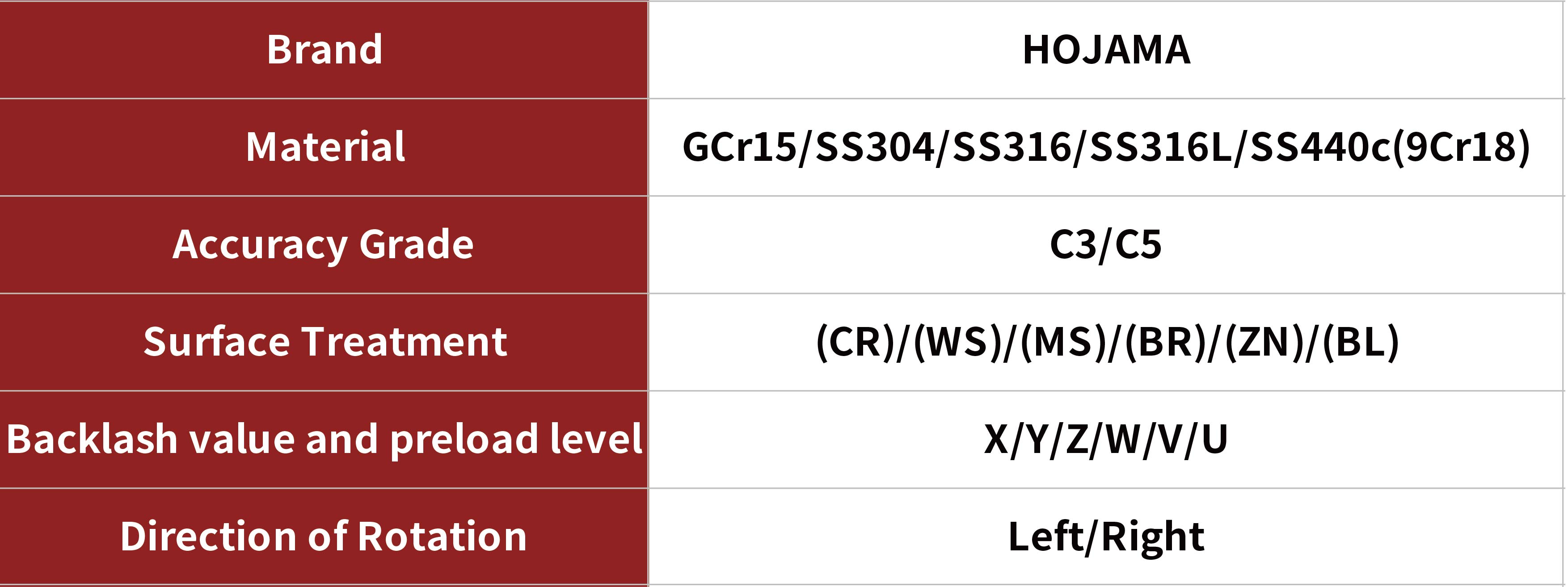

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

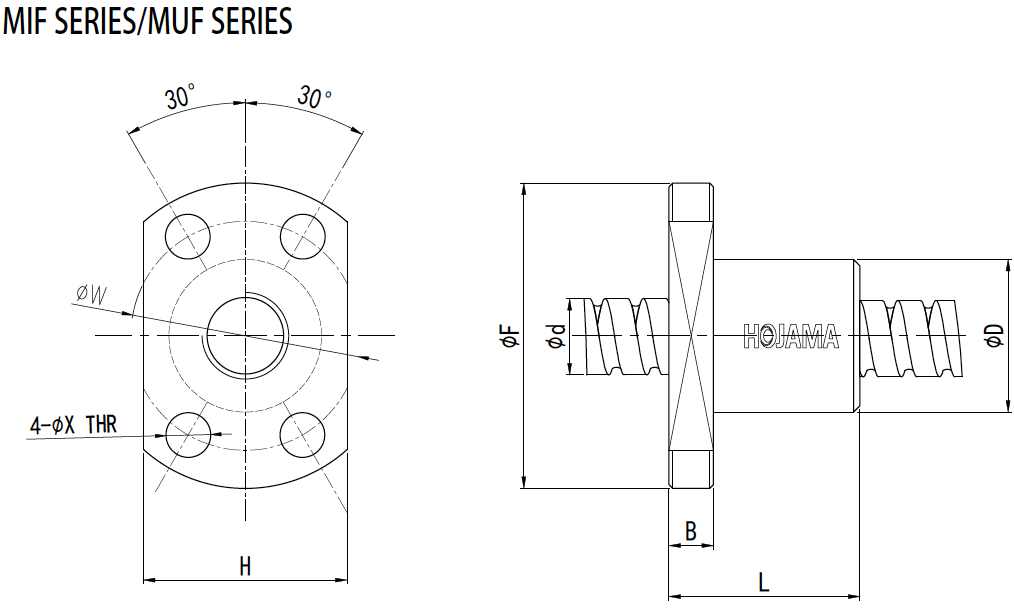

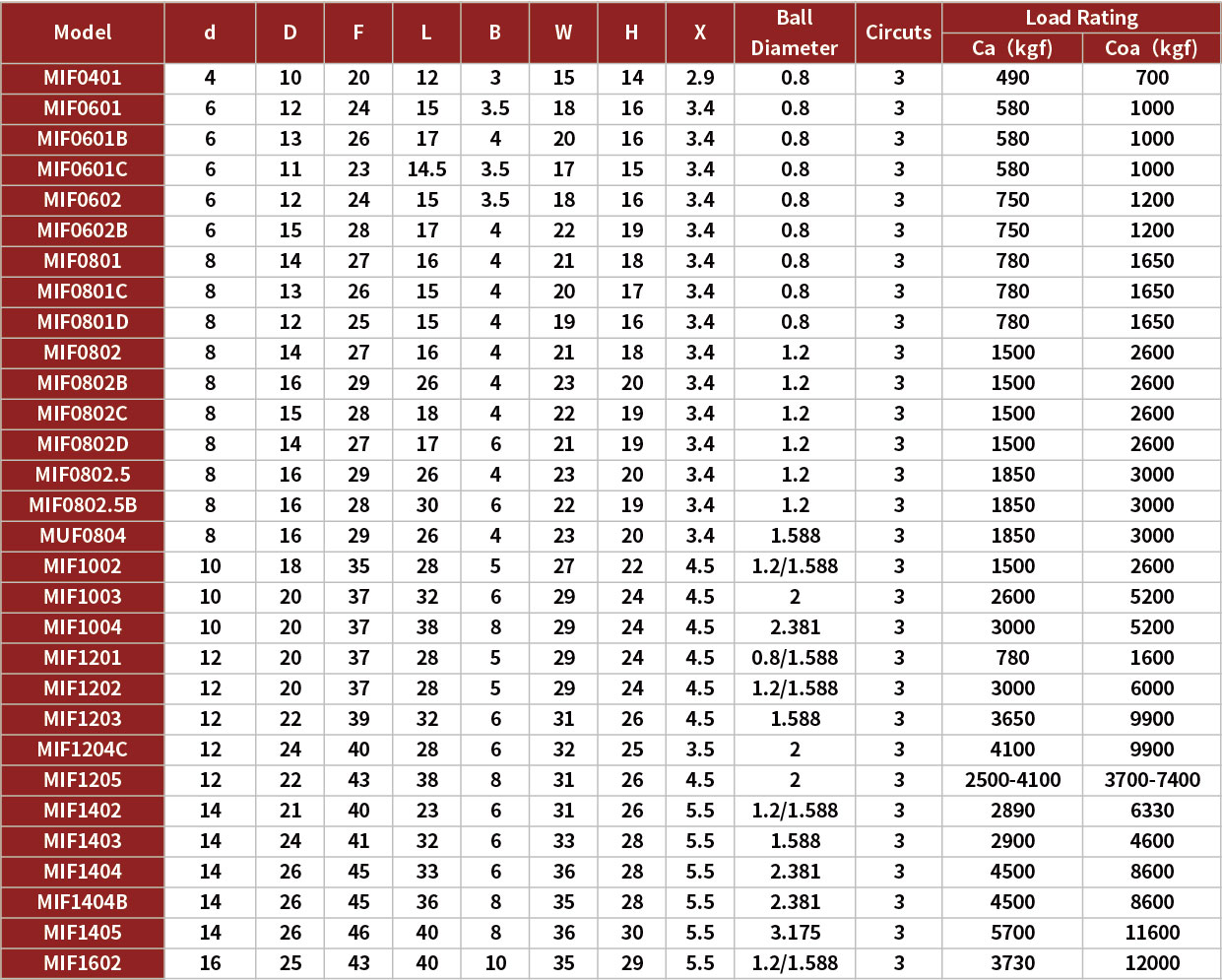

1. The high-speed ball screw is an 8mm diameter screw with a 2mm lead. It features a metal ball screw shaft, a standard round nut with a flange, a floating deflector, and steel balls. The shaft end can be customized according to your requirements. The high-rigidity ball screw set is available in an accuracy grade of C3/C5, ensuring suitable for various machine needs.

2. The precision of Miniature Ball Screws is assured because of the meticulous quality control system. It is advised not to detach the ball screw nut from the ball screw, as they are specifically matched; reinstallation may prove challenging.

3. Mini ball screw application:

These high-speed micro ball screws are widely used in industrial machineries, such as CNC machines, robots, aerospace equipment, semiconductor manufacturing, etc. achieving higher production efficiency and better motion control.

How to Select a Ball Screw

1. Selection of Nominal Model

The selection of the nominal model mainly refers to the nominal diameter and lead of the screw. At the initial stage of design, the selection of the screw model is primarily based on the technical requirements of the machine tool, including load and rapid traversal speed. After the initial selection, it is necessary to conduct calculations and verification. Only when the calculation results meet the requirements can the model be finally determined.

2. Selection of Lead Accuracy

The accuracy of the screw largely affects the positioning accuracy of CNC machine tools. Among the accuracy parameters of the screw, the lead error has a relatively obvious impact on the positioning accuracy of the machine tool. The accuracy of the screw is mainly divided into 7 grades, with grade 1 being the highest, and the accuracy decreases in sequence.

3. Support Method

In addition to the above-mentioned nominal model and lead accuracy, it is also necessary to determine the support method. Generally, in the design of CNC machine tools, there are many options for the support method of the screw, and the corresponding characteristics are also different. Users need to choose according to actual usage requirements.

1. To determine the actual price of a HOJAMA Miniature Ball Screw, you need to provide detailed CAD or 3D drawing parameters along with the required quantity. For an accurate quote, it is best to share these specifications with the relevant HOJAMA representatives. They will then be able to offer a tailored quotation and provide precise pricing information based on your specific needs.

2. As a company committed to quality and user experience, we are pleased to offer product samples for your evaluation.

3. Lead time: 15-25 days

Product Categories : Miniature Ball Screws > 8mm Diameter Ball Screw