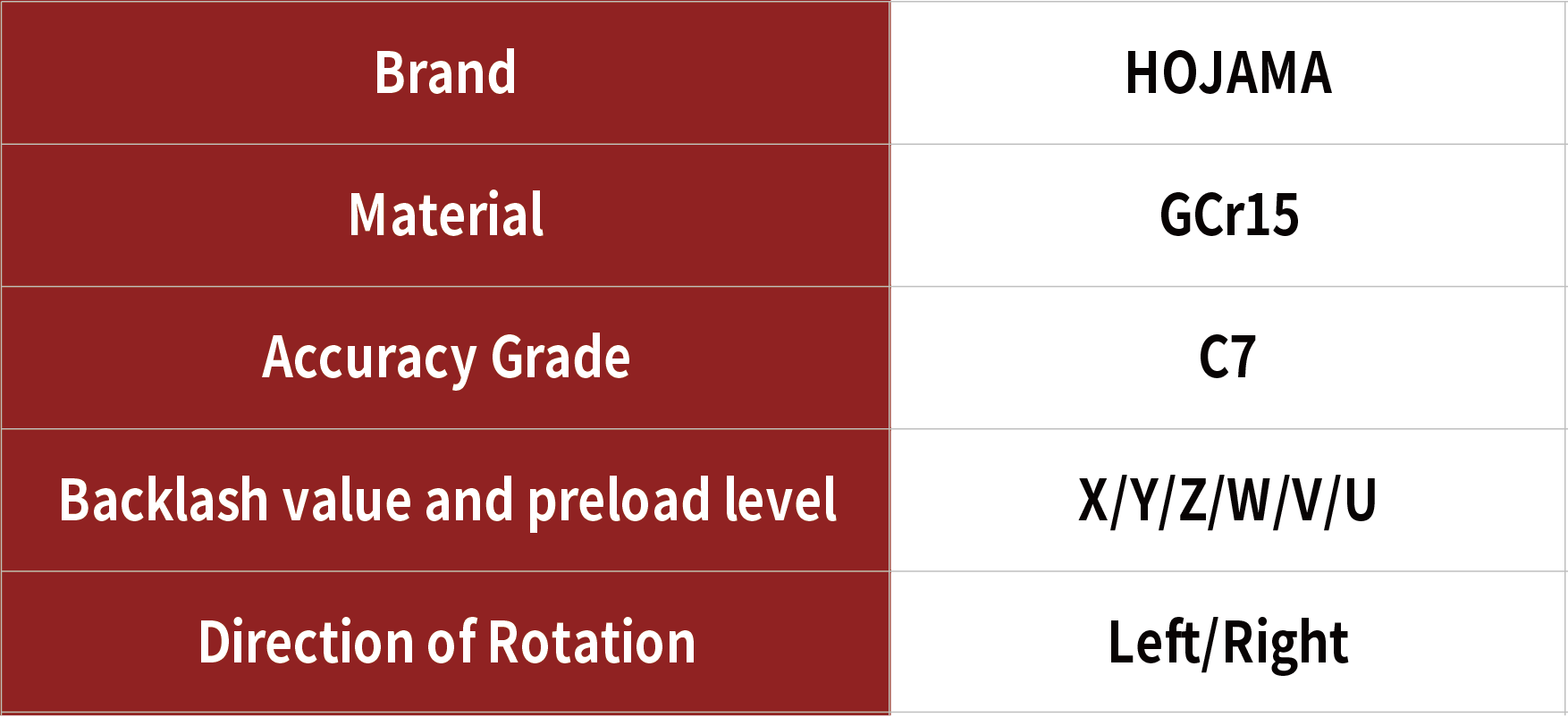

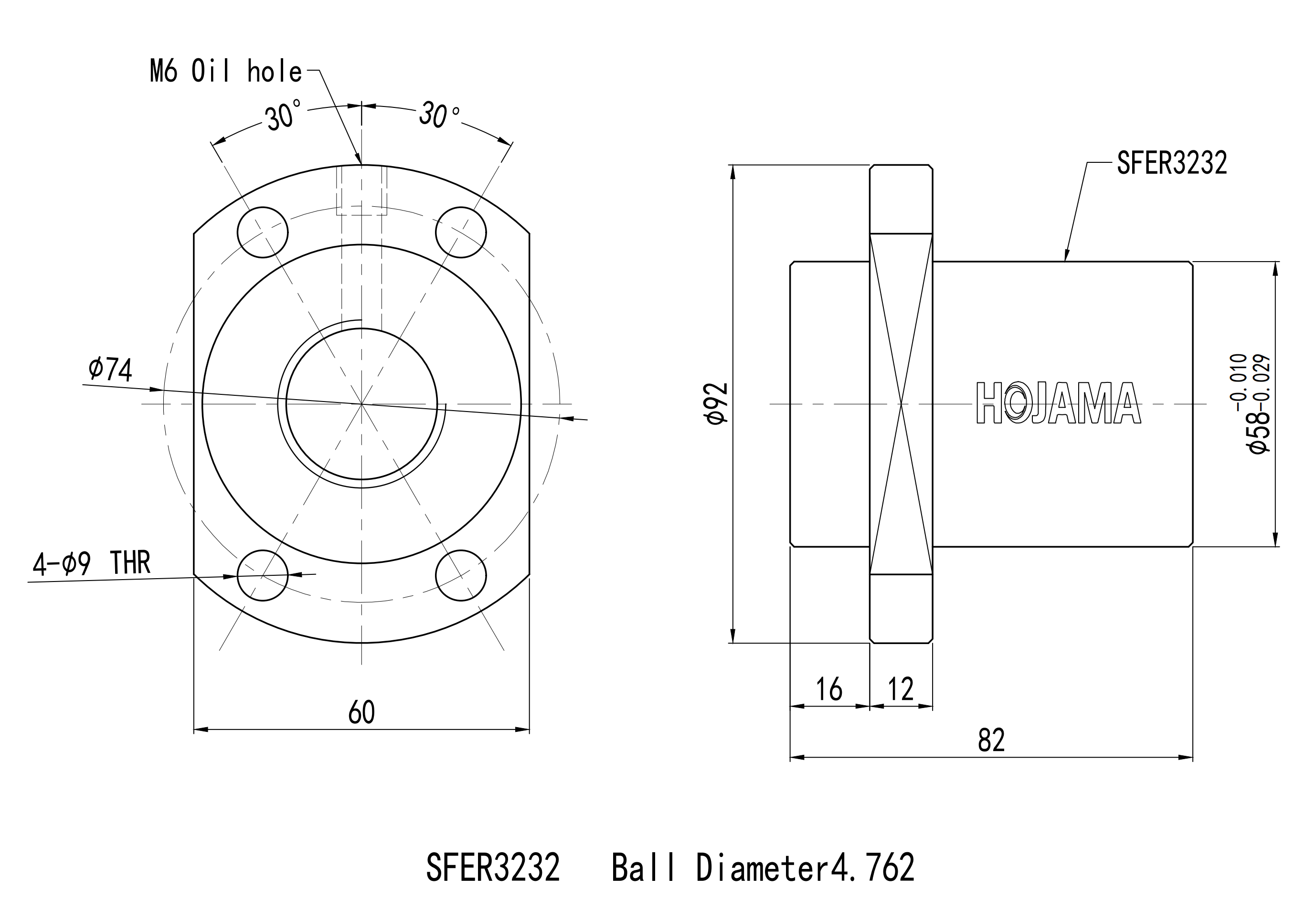

Model No.: SFE3232

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Rolled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

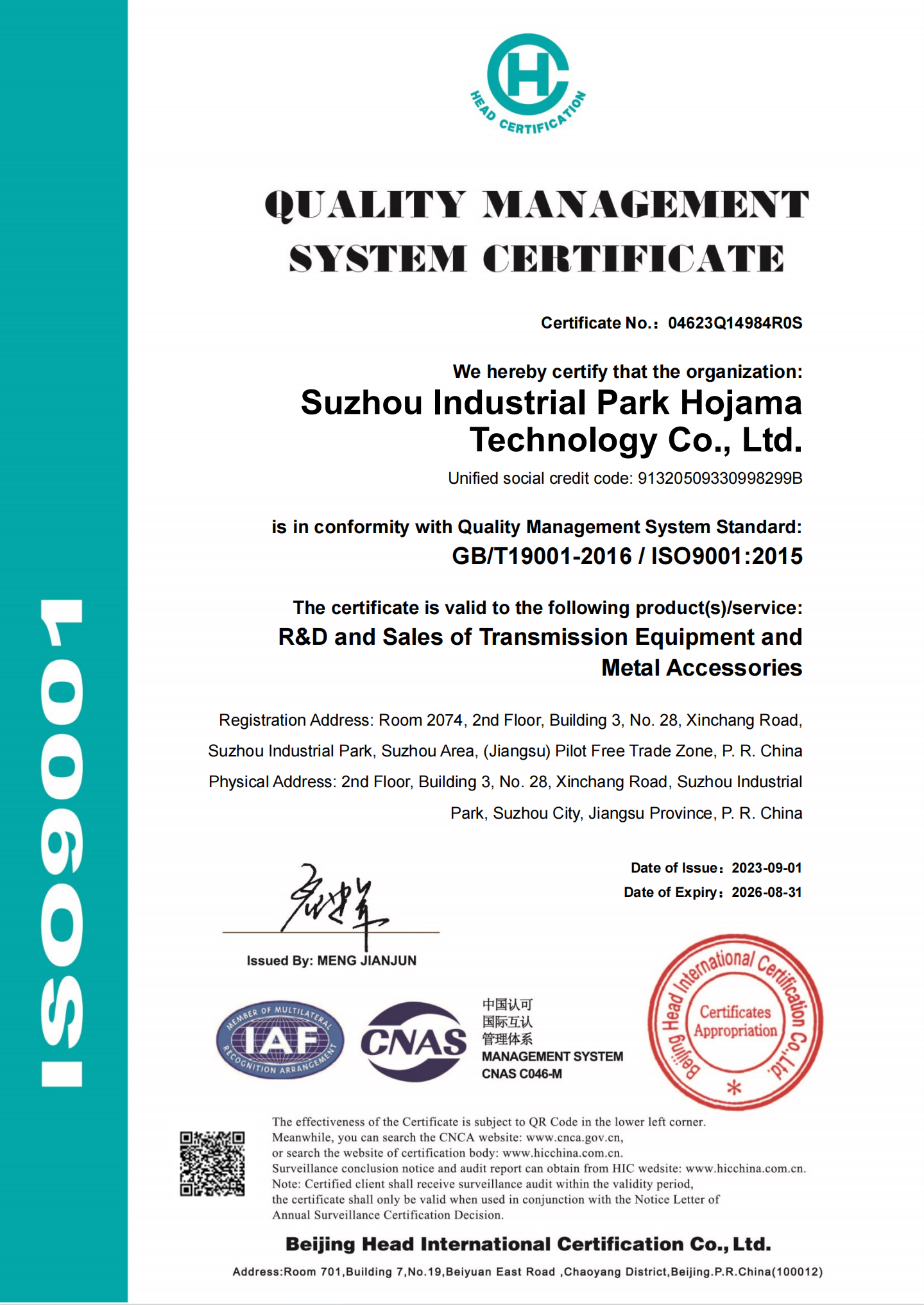

Certificate: ISO9001:2015

Port: Shanghai,Zhoushan,Dalian

Product Categories : Rolled Ball Screws > 32mm Diameter Rolled Ball Screw