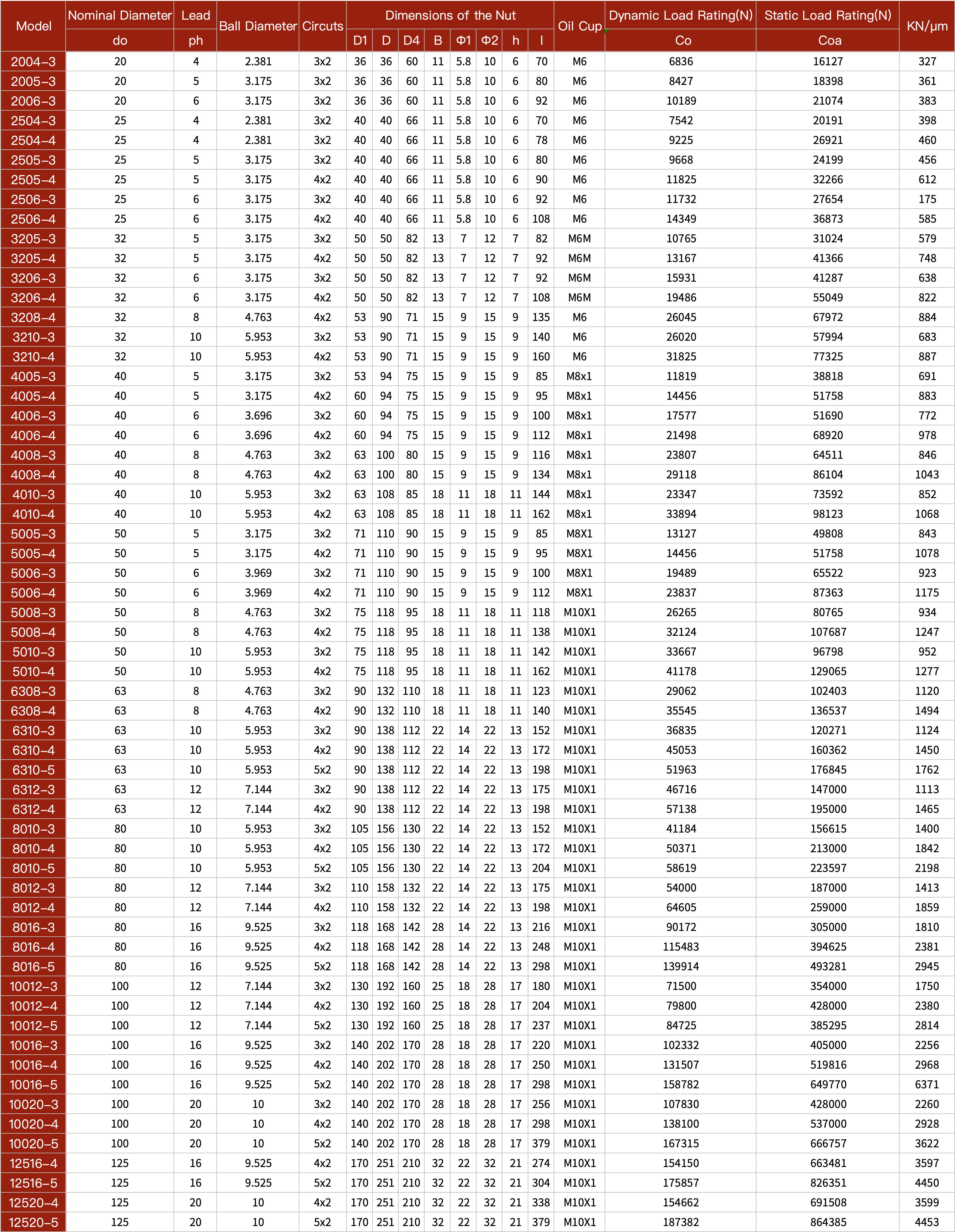

Model No.: GD4005-4-515-586-C5

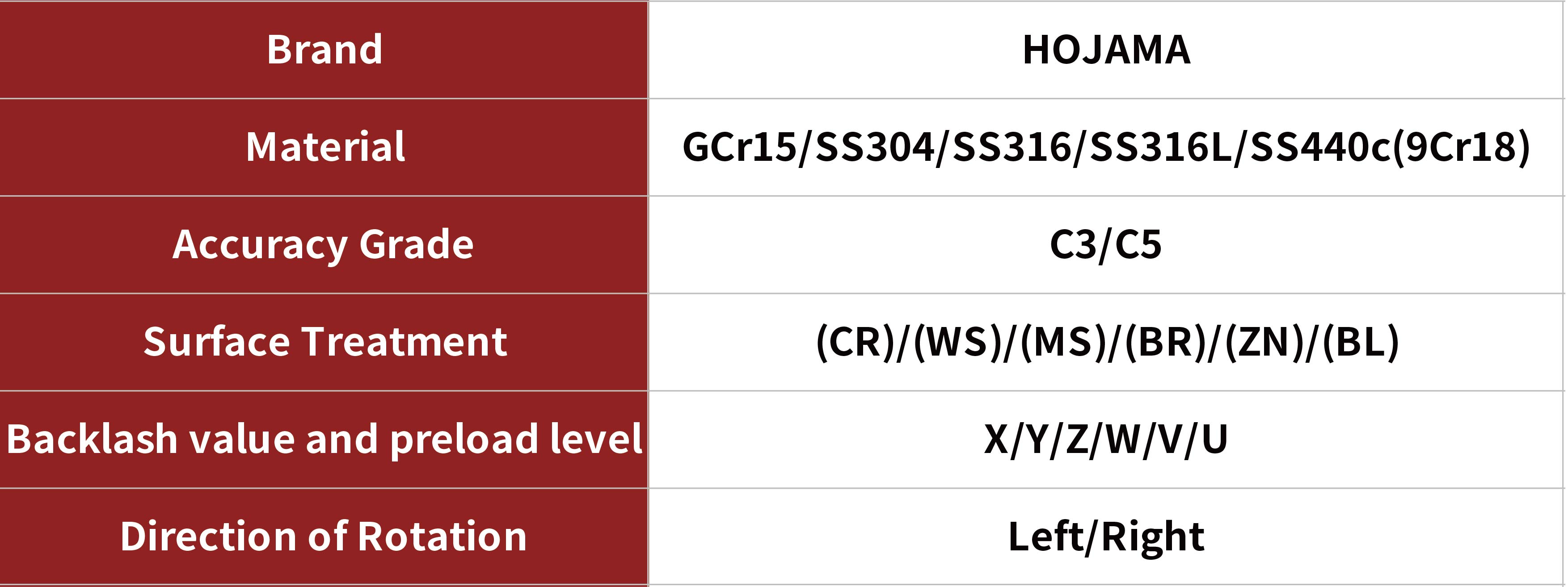

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

For ground ball screws, we offer two precision grades, including C3 and C5. The position accuracy is up to 0.008mm.

Before the shipment, we must inspect the ball screw assembly strictly and can provide the inspection report.

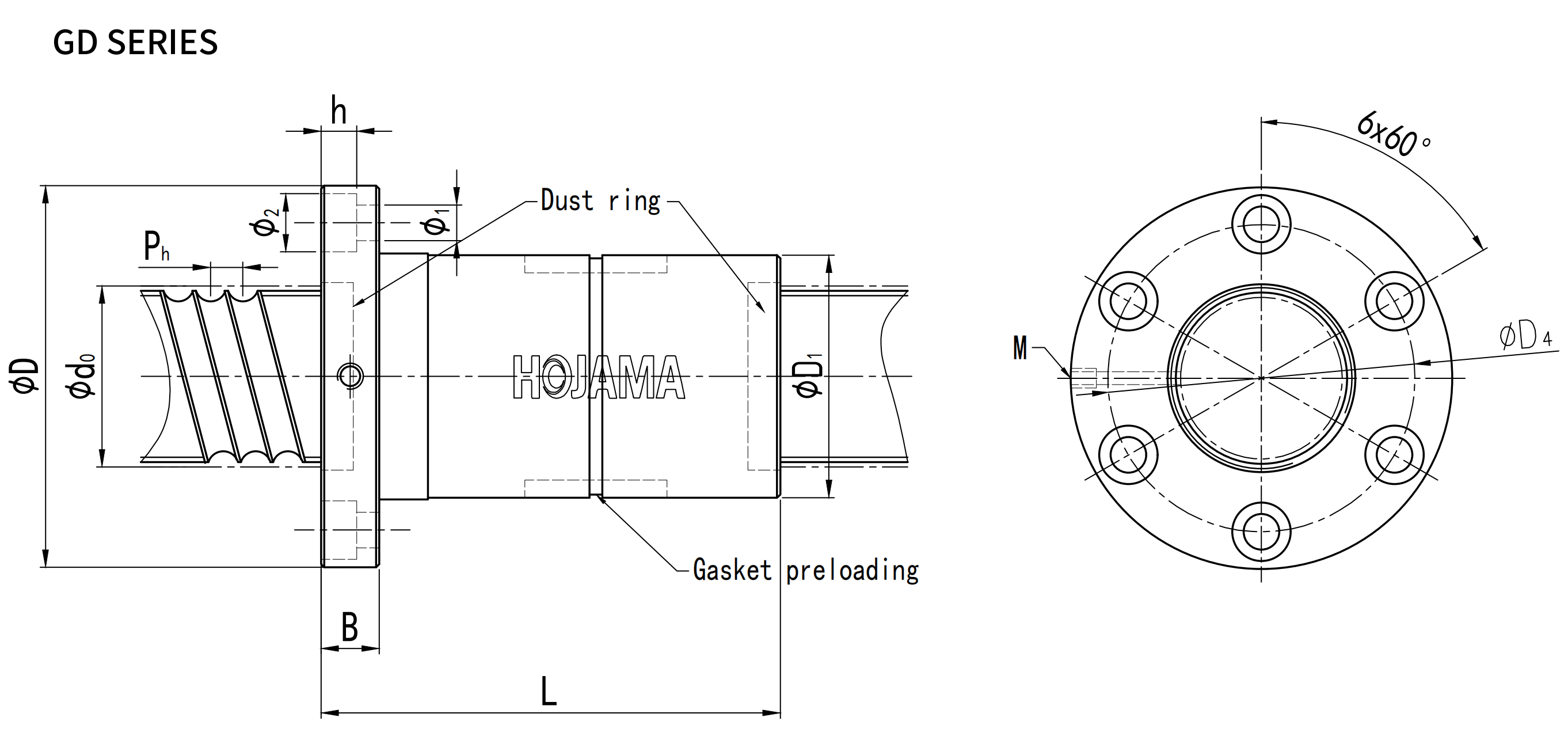

To meet the different requirements, we also can provide a customization support of the linear ball screw, including the dimension, material, machining method and more.

For the price of precision ball screw, please consult us with the product drawing.

Product Categories : Precision Ball Screws > 40mm Diameter Ball Screw