What are the differences between high assembly and low assembly in linear guides?

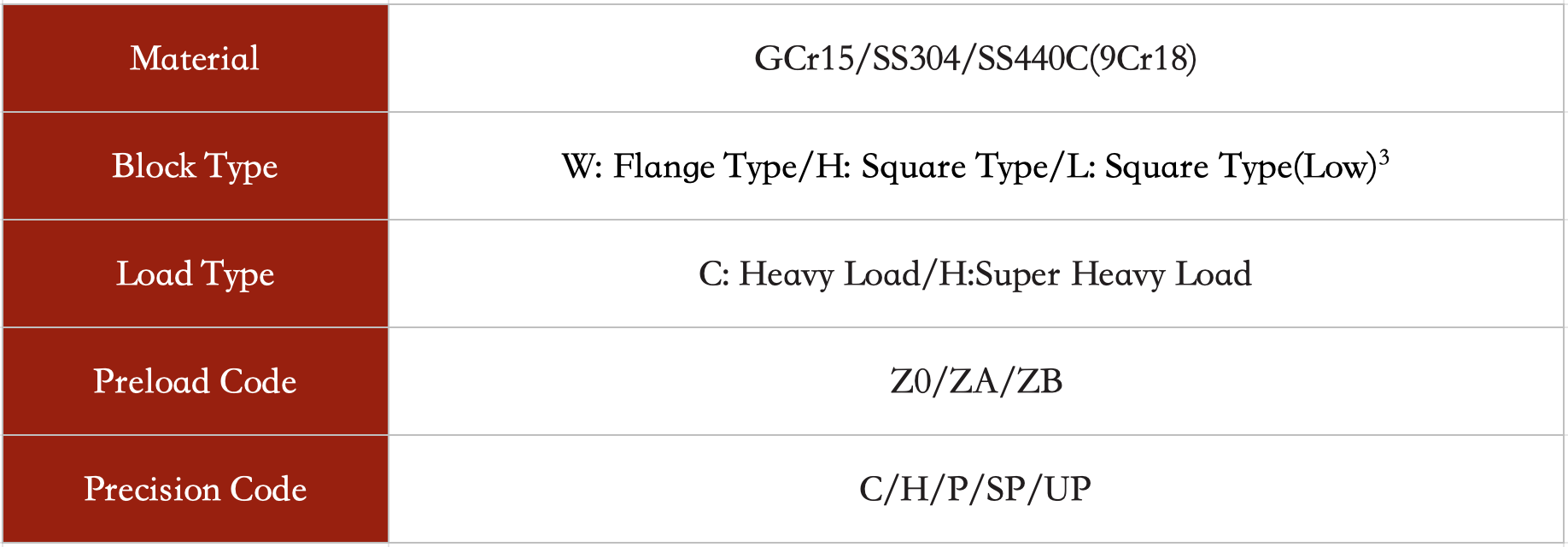

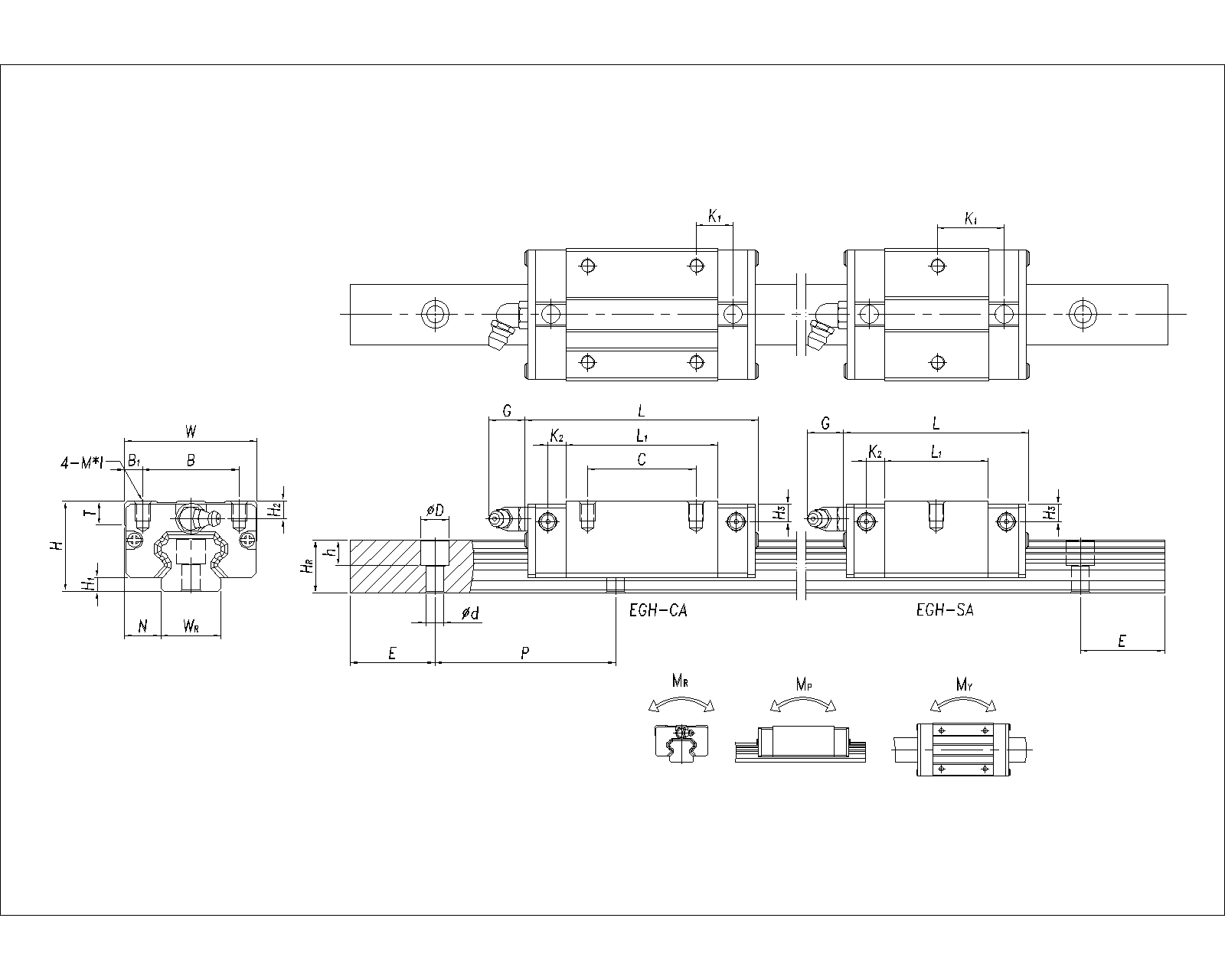

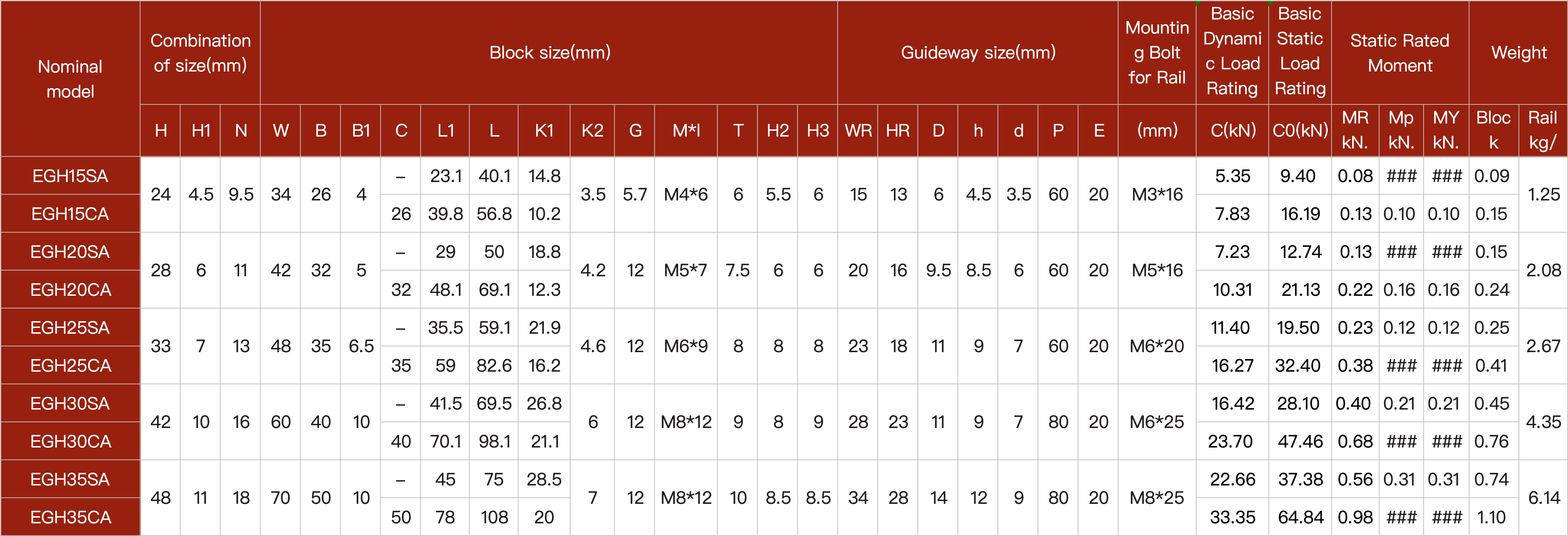

The combination height types of linear guides are primarily divided into two categories: high-assembly type and low-assembly type. As the name suggests, the combination height (from the bottom surface of the rail to the top surface of the slider) of the high assembly type is higher, while that of the low assembly type is lower. Depending on the specification size, the difference ranges from 2 to 7 mm, which is caused by different slider height standards and is generally irrelevant to the rail.

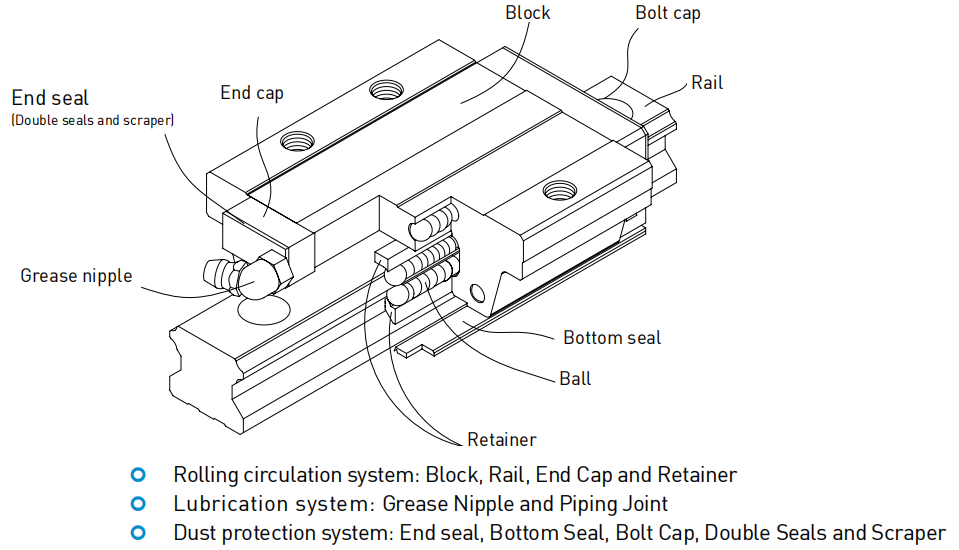

High-assembly linear guides are four-column single-arc tooth contact linear guides and are also heavy-duty precision linear guides with a well-structured design. Compared to other linear guides, they improve the load-bearing and stiffness capabilities. The four-way load-bearing characteristics and automatic centering function can absorb the assembly errors of the installation surface, meeting high-precision requirements.

Low-assembly linear guides, high stiffness, heavy load capacity, and four-directional load, adopt a four-row steel ball load-bearing design. Their automatic centering function absorbs installation errors to meet high-precision requirements. By combining the reduction of the combination height and the shortening of the slider length, they are very suitable for high-speed automation industries and equipment with small mechanical and space requirements.

High-assembly linear guideways are suitable for use in environments with large installation space and heavy loads, such as grinders, milling machines, lathes, boring machines, drilling machines, and comprehensive processing machines.

Low-assembly linear guideways are suitable for use in environments with small installation space and light loads, such as engraving machines, packaging machinery, and semiconductor machinery.

When requesting a quotation and lead time, please provide the product drawing.

Product Categories : Linear Guideways > EG Seies Linear Guideways