Model No.: MEF0808

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

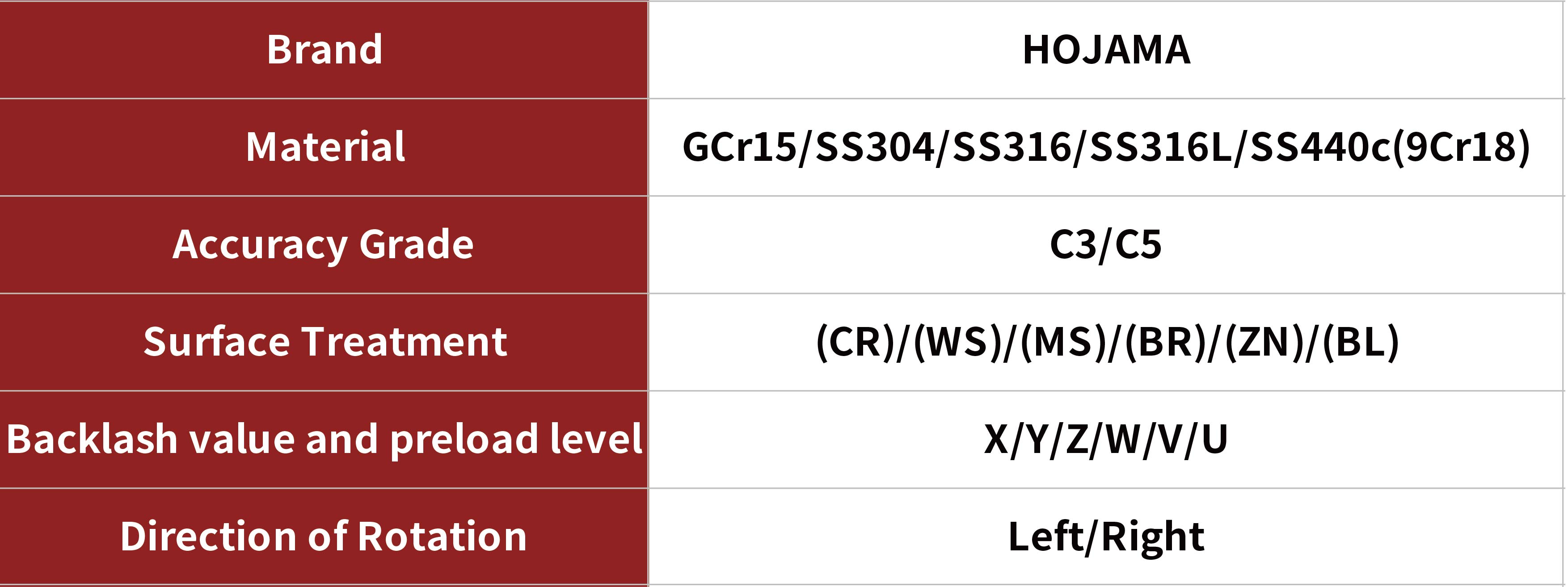

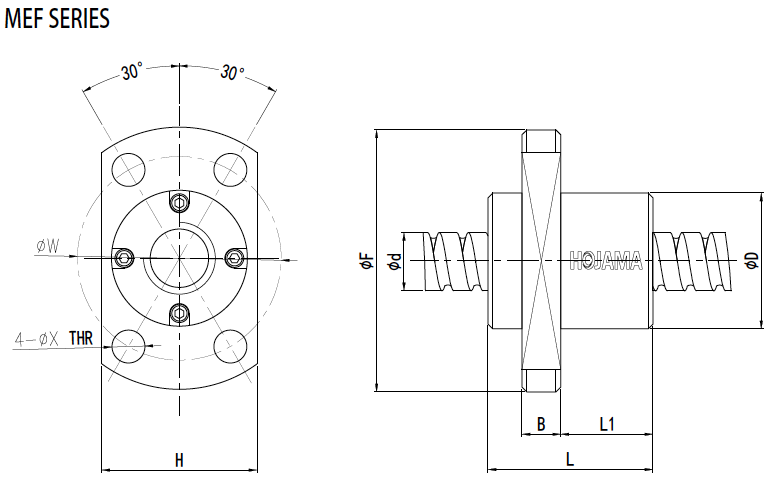

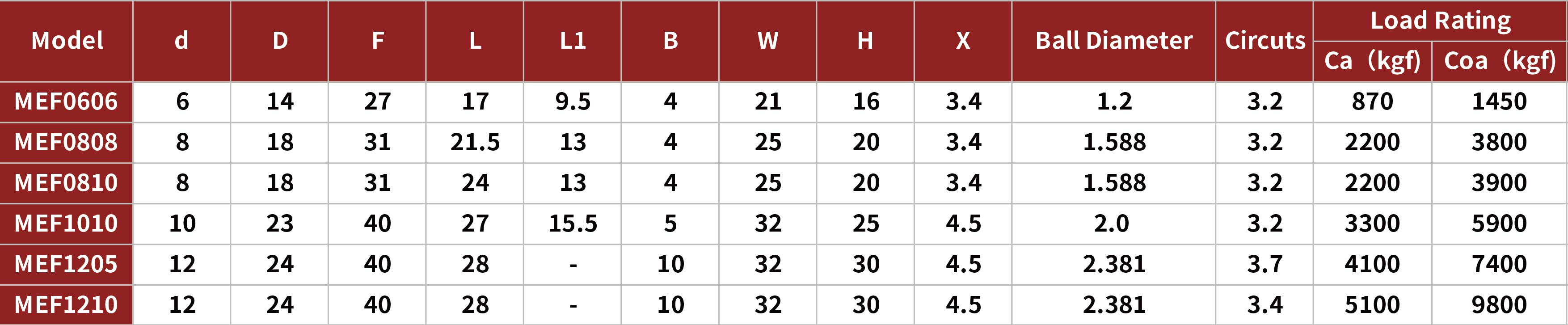

The HOJAMA Miniature Ball Screws have a diameter ranges from 4cm to 16cm and their precision grade are available in C3 or C5. Their hardness can be improved through specialized surface treatments. Additionally, six clearance and preload levels are available to eliminate gaps between the steel balls and the nut’s internal grooves, enhancing the linear screw’s rigidity.

Lead/Pitch: 8mm

Nut Type: Standard Nut

Cycle Mode: End Cover Return

Nut Shape: Round Nut with Flange

Installation Methods for Ball Screw Assemblies

One end of the screw is fixed, and the other end is free. The bearing at the fixed end bears both axial and radial forces. This support method is suitable for short screws with small strokes.

One end of the screw is fixed, and the other end is supported. The bearing at the fixed end bears both axial and radial forces; the bearing at the supported end only bears radial forces and can float slightly axially. This design avoids or reduces bending of the screw due to its weight, while allowing thermal deformation of the screw to extend freely toward one end.

Both ends of the screw are fixed. Bearings at both fixed ends can bear both axial and radial forces. This support method allows appropriate pre-tensioning to be applied to the screw, improving the support rigidity of the screw and partially compensating for thermal deformation of the screw.

In this setup, the nut rotates while moving axially along the fixed screw. Since the screw remains stationary, it avoids limitations from critical rotational speeds and eliminates issues associated with high-speed operation of slender ball screws. The nut has low inertia and moves flexibly, enabling high rotational speeds. This method also allows greater pre-tensioning to be applied to the screw, enhancing support rigidity and compensating for thermal deformation.

HOJAMA ballscrews use steel balls for motion transfer, achieving over 90% efficiency and reducing drive torque to one-third of traditional screws.

The high-performance screw with ball offers high positioning accuracy, with deviations as low as 0.002 mm per 300 mm.

These high-precision screws in the ball feature a superior surface finish due to ISO quality control and ultrasonic cleaning.

The strict control of design and materials results in these anti backlash CNC ball screw with a longer lifespan.

Our linear motion ball screw assemblies can operate simultaneously with smooth and consistent performance.

1. To calculate the actual price of the product, you must provide us with CAD or 3D drawings and the quantity of the product, which our specialists will then calculate.

2. Lead time: 15-25 days

3. HOJAMA offers a sample for you to assess the quality. For more details, please contact HOJAMA.

Product Categories : Miniature Ball Screws > 8mm Diameter Ball Screw