Model No.: MIF1205

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

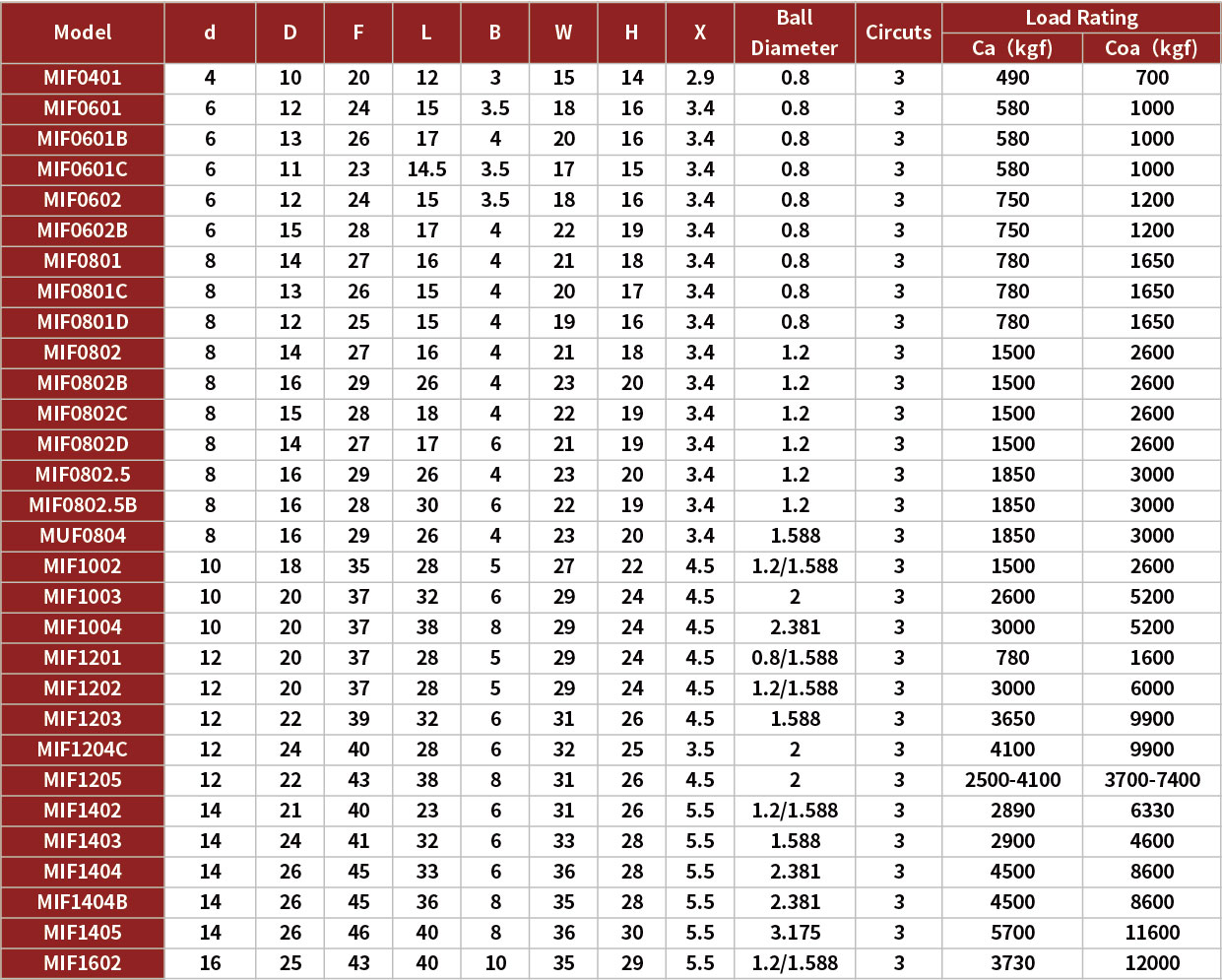

MIF1205: 12mm Diameter Ball Screw

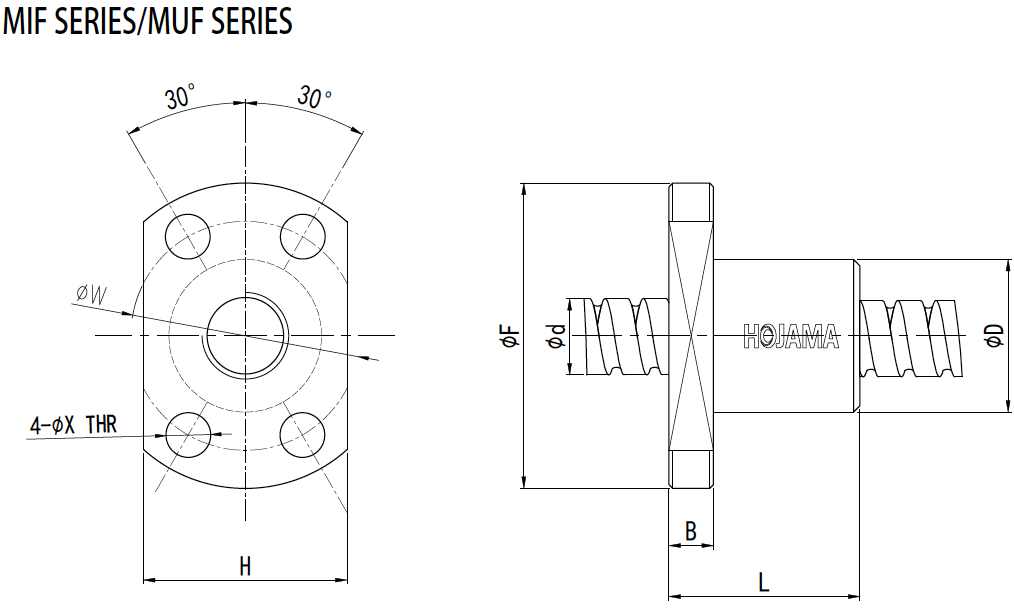

The Miniature Ball Screw is a high-precision mechanical linear actuator widely used in automation and precision machinery. It is comprised of a screw, a nut, matching grooves, and rolling steel balls.

A key advantage of this design is the rolling ball mechanism, which greatly reduces friction between the screw and the nut. This reduction in friction leads to enhanced power efficiency and superior motion accuracy. For instance, HOJAMA ball screws offer an operational efficiency of up to 96% or higher, and their precision can reach grades C3 or C5, making them well-suited for demanding applications.

The screw shaft is a crucial component of the ballscrew, typically a long cylindrical part with internal ball grooves. This shaft withstands rotational forces and facilitates smooth ball movement. This design ensures that HOJAMA ball screws excel in high-load and high-precision applications, providing modern mechanical systems with reliable and efficient motion solutions.

Key advantages of Miniature Ball Screws:

1. High Efficiency

The rolling motion of the balls between the screw and nut significantly reduces friction, resulting in higher power efficiency for micro ball screws.

2. Long Service Time:

The rolling contact of ball screws and ball nuts minimizes wear, resulting in a longer lifespan compared to traditional sliding contact screws. Micro ball screws typically offer even greater longevity.

3. Versatile Adaptability:

The compact design of micro ball screws allows them to fit into various complex and confined spaces, meeting the needs of diverse industrial and technological applications.

4. Low Maintenance Requirements:

The design of 3d printer ballscrews reduces friction and wear, which typically results in lower maintenance needs. This contributes to reduced long-term operational costs.

NOTE:

1. The prices listed on the page are for reference only. For specific pricing, please consult HOJAMA.

2. The delivery time for samples is 15 to 25 days.

3. Samples available upon request.

Product Categories : Miniature Ball Screws > 12mm Diameter Ball Screw