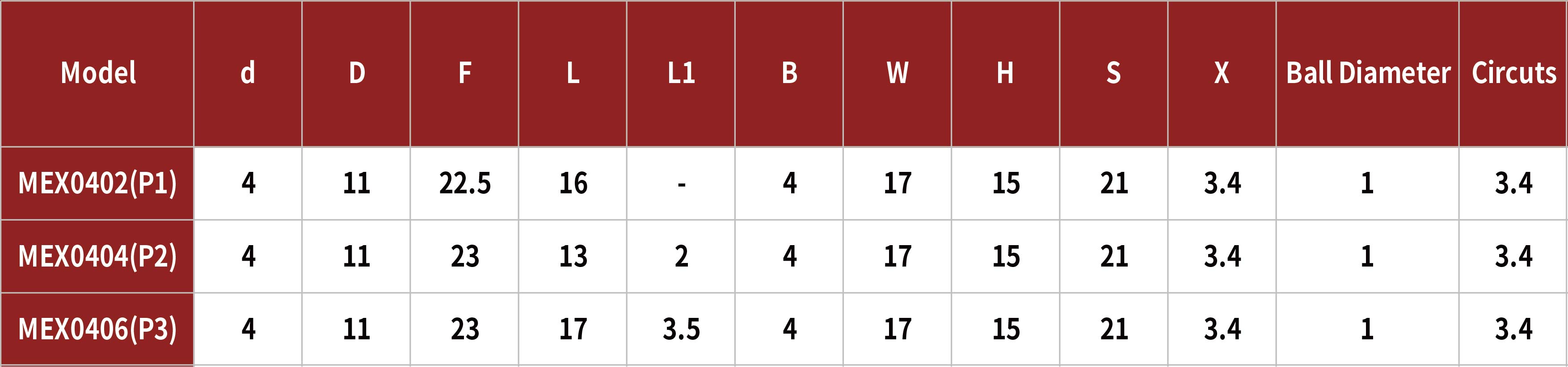

Model No.: MEX0402(P1)

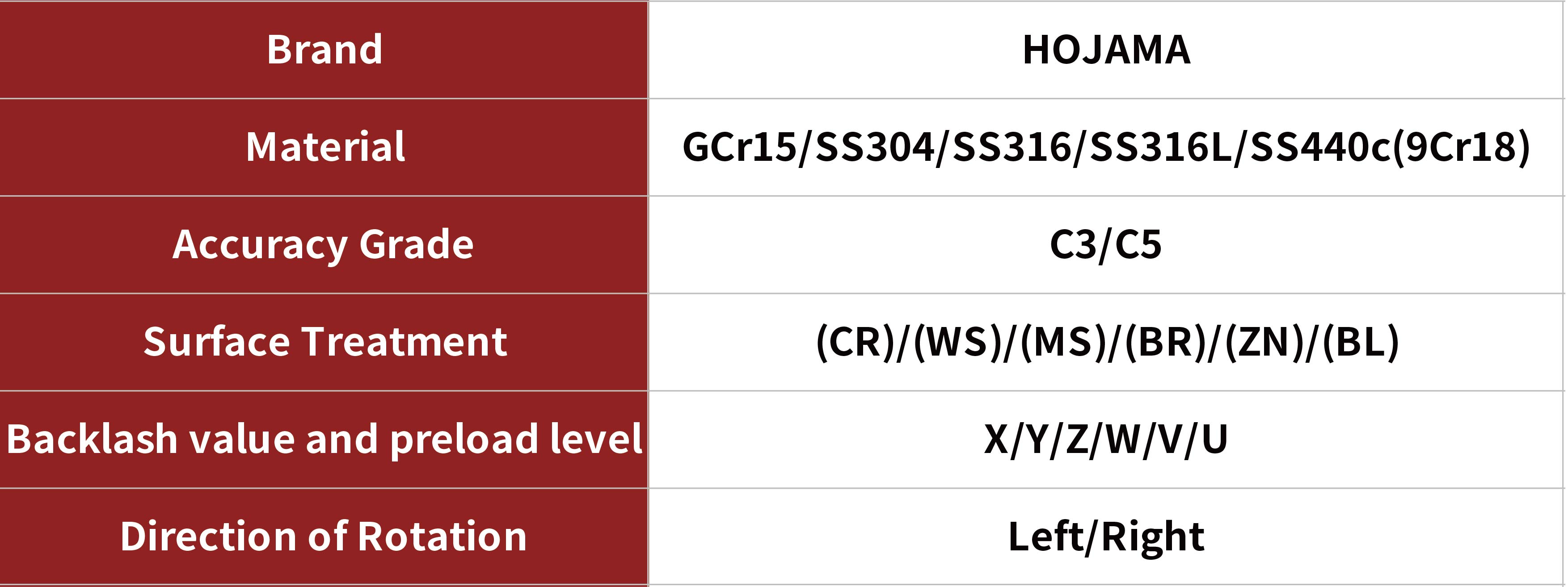

Brand: HOJAMA

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Gear, Pump

Processing Technology: Milled Thread

Place Of Origin: China

Packaging: Wooden box

Productivity: 30000 sets/month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30000 sets/month

Certificate: ISO9001:2015

Port: Shanghai,Dalian,Zhoushan

Hojama ball screw and nut is widely used in industrial machinery and precision instruments due to its low friction, high precision, and efficiency. In particular, the Miniature Ball Screw, known for its compact size, is indispensable in a variety of small precision devices such as medical equipment, precision instruments, aerospace, and automation. It converts rotary motion from a motor into linear motion through relative rotation with a nut, enabling high-precision displacement and positioning.

1. Keep the screw clean. Regularly clean the dust, debris, and other impurities on the surface of the screw to prevent them from entering the interior of the screw and affecting its operation.

2. Ensure good lubrication. According to the usage conditions, add appropriate lubricating oil or grease at specified intervals to enable the balls to roll smoothly on the screw and reduce wear.

3. Avoid excessive load. Do not allow the screw to bear a load exceeding its bearing capacity to prevent deformation or damage of the screw.

4. Ensure accuracy during installation and use. Avoid damage to the screw or reduction in accuracy caused by incorrect installation or operation.

5. Regularly check the operating status of the screw, including the presence of abnormal noise, vibration, etc. If any problems are found, promptly carry out maintenance or replace damaged components.

6. Pay attention to environmental factors. Avoid the screw working in harsh environments for a long time, such as high temperature, high humidity, and corrosive environments. Take protective measures when necessary.

7. Maintain the components matched with the screw to ensure the good operation of the entire transmission system.

8. When the screw is not in use for a long time, protective measures and maintenance should also be taken to prevent rust and other situations.

1. HOJAMA is pleased to offer sample support, allowing you to request samples for testing and evaluation.

2. The cost of these samples depends on the drawing specifications and the quantity of the products.

3. The delivery time is approximately 15-25 days, depending on the product specifications and quantity.

4. You can provide us with CAD and 3D drawings, and our experts will review them to assess feasibility and offer guidance and recommendations. For orders or inquiries, please don’t hesitate to contact HOJAMA.

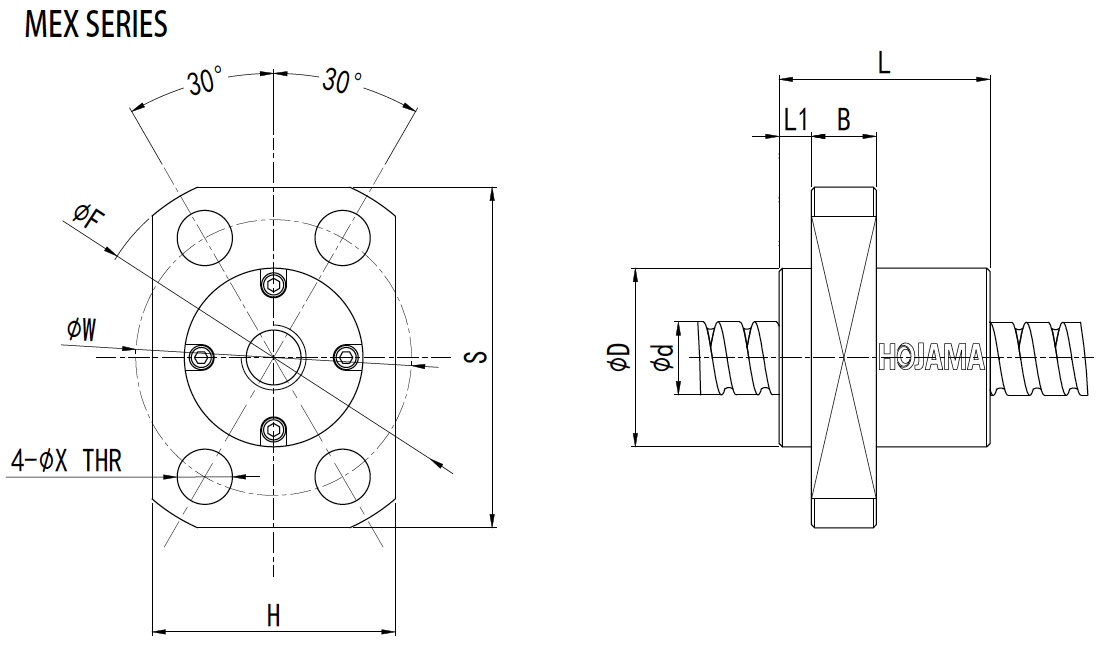

Product Categories : Miniature Ball Screws > 4mm Diameter Ball Screw