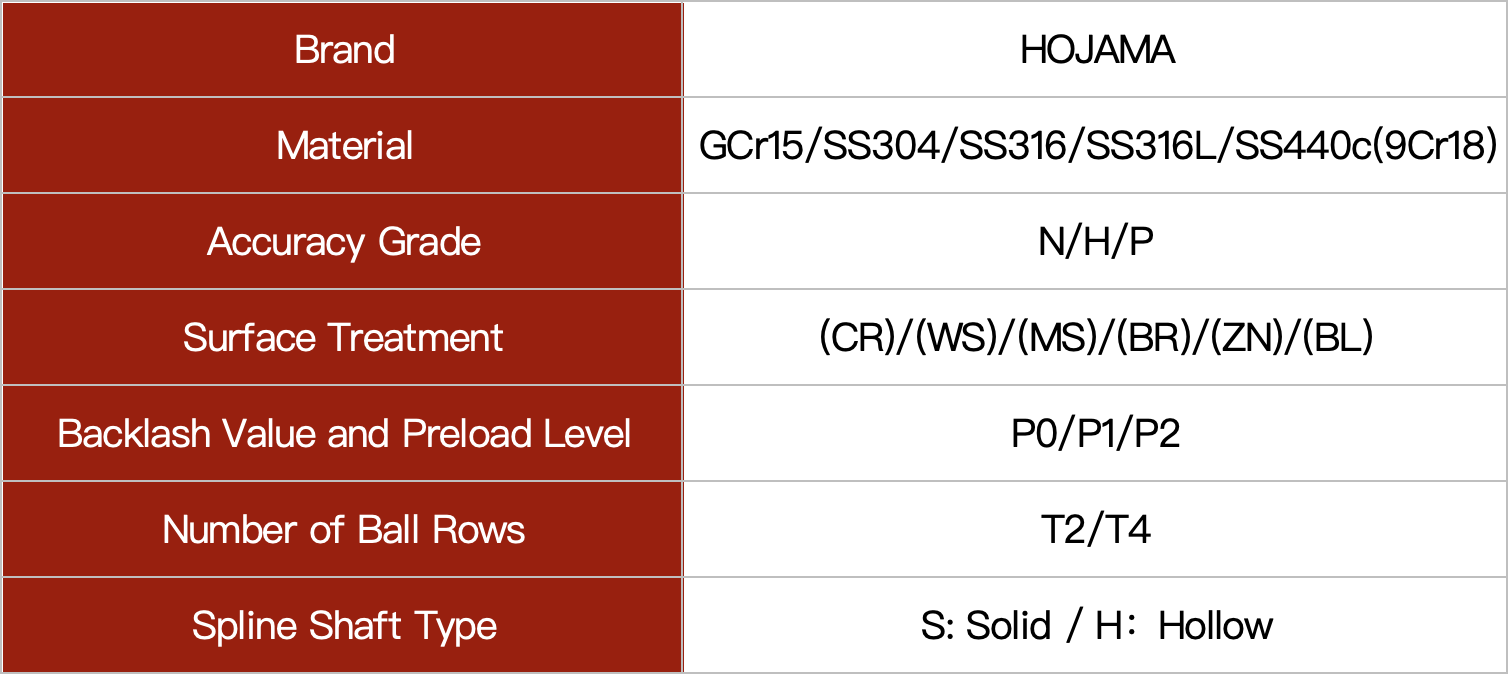

The linear ball spline known also as ball bearing spline or recirculating ball spline, it combines a screw spline with a nut integrated with balls and an efficient ball return mechanism, complete with return tubes or caps.

Diverse Types and Adaptability

1. Structural Varieties:

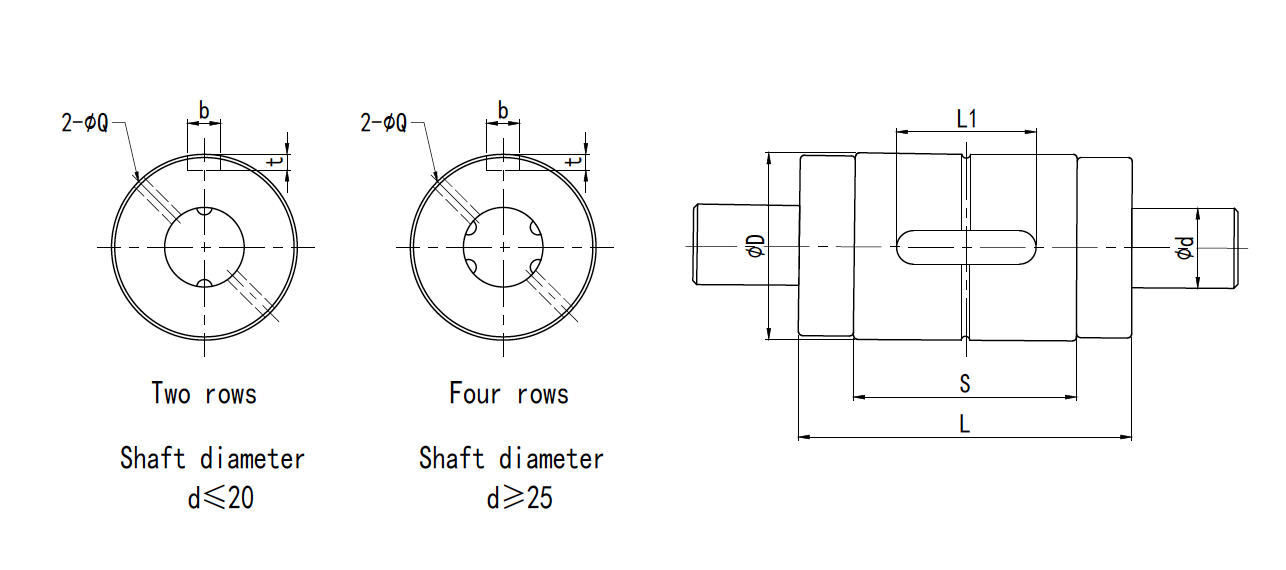

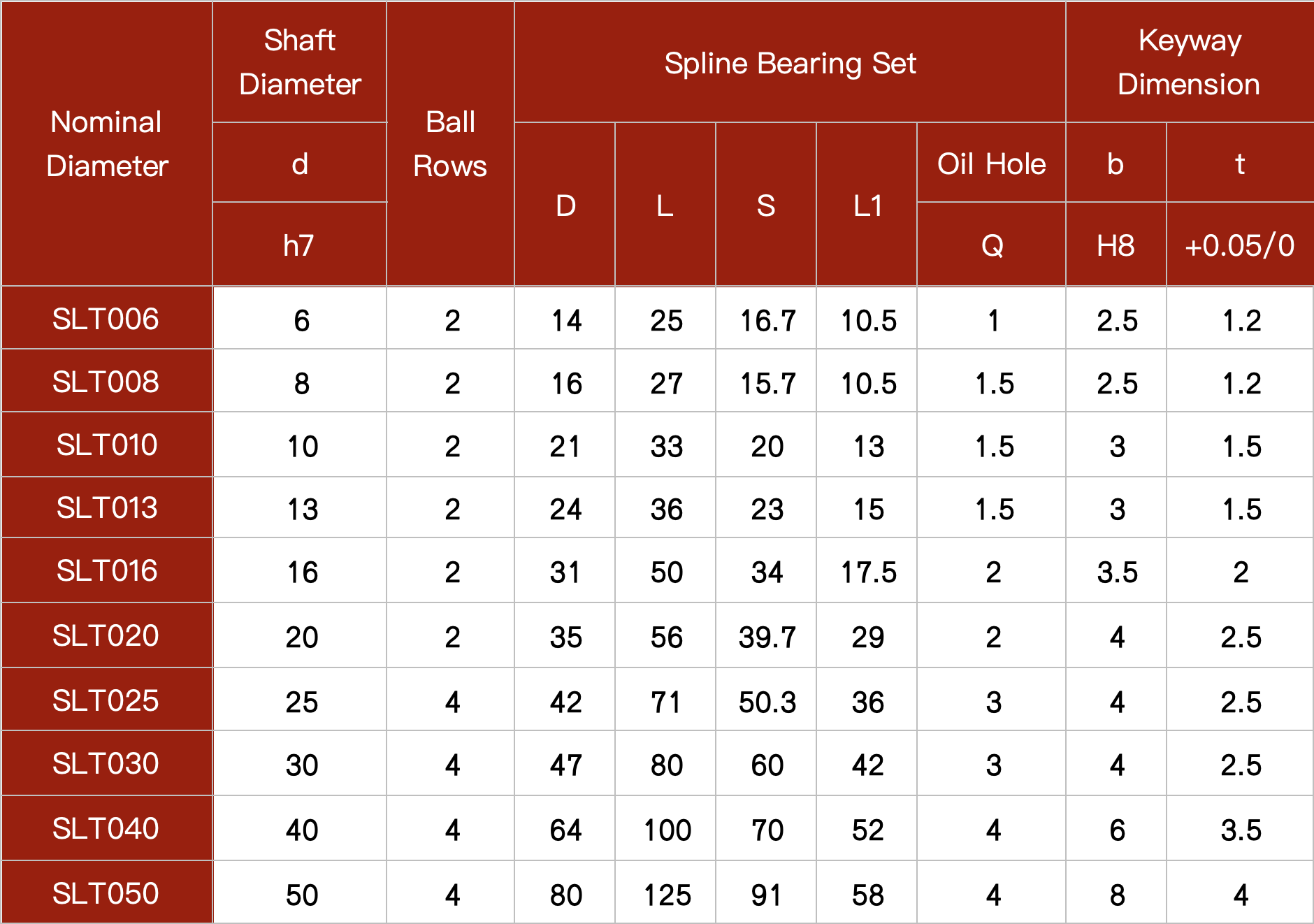

Ball Splines come in two main types: the flange-type SLF and the non-flange SLT. Hojama also can provide you with SOT, SOF, and LT. Based on the shaft diameter, the contact path of the steel balls can be configured in 2 rows (180°) for models SLF/SLT6-20 or 4 rows (70°) for models SLF/SLT25-50. There's also the option of hollow shafts, providing flexibility to meet different engineering requirements.

2. Vibration and Shock Resistance: Thanks to its unique design, this ball spline is well-suited for environments with excessive vibration and shock loads. It can maintain stable operation, making it a reliable choice for industries where equipment is subject to harsh conditions.

Extensive Application Scenarios

1. Automation Machinery

Our High Precision Linear Ball Spline is crucial in automation. In machine tools, it ensures accurate movement for high-precision machining. For robots, it enables smooth motion, boosting performance.

2. Advanced Manufacturing and Aerospace

In semiconductor steppers, the ball spline system is vital for accuracy. In aircraft, missiles (especially fly-by-wire systems), move control surfaces. In car power steering, they convert motor rotation to steering rack motion, improving safety.