Since ball screws operate with rolling motion, they are more efficient compared to Lead Screws, achieving a conversion efficiency of η = 88% -96% for rotary motion to linear motion. Additionally, Precision Ball Screws, which are machined to a fine degree, can achieve micron-level feeding accuracy. When used in lifting mechanisms, measures such as braking must be implemented, such as using servo motors with brakes.

Ball Screw Mounting Method

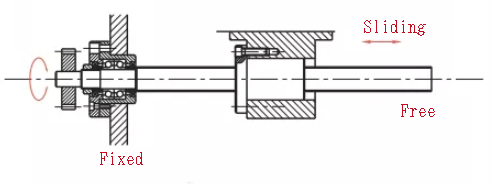

1. Fixed-Free

This installation method has a low load capacity and low axial stiffness, making it suitable only for short screws.

Characteristics: This method features a simple structure, with low axial stiffness and critical speed, resulting in poor stability for the screw. It is commonly used for short strokes and vertical drive systems where one end is free, typically combined with angular contact bearings.

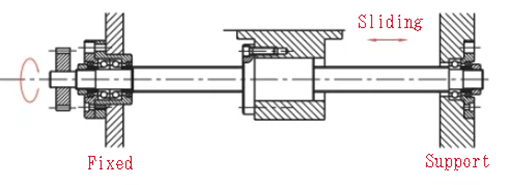

2. Fixed-Support

One end is fitted with a thrust bearing, while the other end is fitted with a deep groove ball bearing. When the ball screw is relatively long, the thrust bearing is fixed at one end, and the deep groove ball bearing supports the other end. To reduce the impact of thermal deformation on the screw, the mounting position of the thrust bearing should be kept away from heat sources.

This installation method is the most typical and commonly used for ball screw mechanisms, suitable for medium speeds with high stiffness and precision.

Note that the supporting end has relatively low rigidity, with one end using a combined angular contact bearing and the other a deep groove ball bearing.

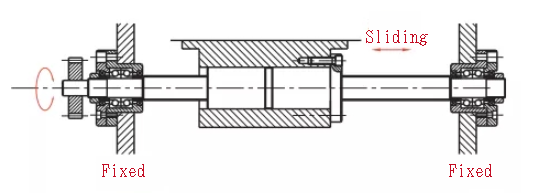

3. Fixed-Fixed

A key feature of this support method is that the ball screw is pre-tensioned to compensate for thermal deformation caused by frictional heat during high-speed rotation, with both ends fitted with combined angular contact bearings in a DT-DB arrangement.

However, this structure has drawbacks; adjustments can be cumbersome. If the pre-tension at both ends is too high during installation, the actual travel of the ball screw may exceed the designed travel, resulting in a larger pitch than intended. Conversely, insufficient pre-tension on the nuts can cause the opposite effect, potentially leading to machine vibration and decreased precision.

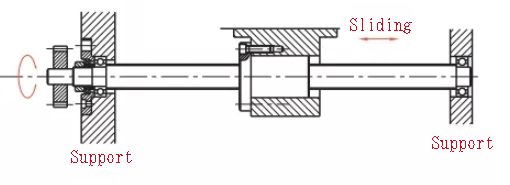

4. Support-Support

This method is suitable for general applications that require medium speed and do not have high demands for stiffness and precision.

The structure is simple, with low rigidity and poor load-bearing conditions, leading to less frequent use. Both ends are fitted with deep groove ball bearings.